Atomizer cleaning and purging – Efficient without cycle time loss

The EcoBell Cleaner D2 and the EcoBell PurgeBox allow fast, safe and environmentally friendly cleaning and rinsing of EcoBell rotary atomizers.

EcoBell Cleaner D2

We fulfill the high demands concerning cycle time and flushing agent consumption with our automated solution. The EcoBell Cleaner D2 completes cleaning the exterior of the atomizer within the cycle speed. Changing color and cleaning the paint channels in the atomizer’s interior take place simultaneously, allowing the system to begin painting the next surface in fifteen seconds.

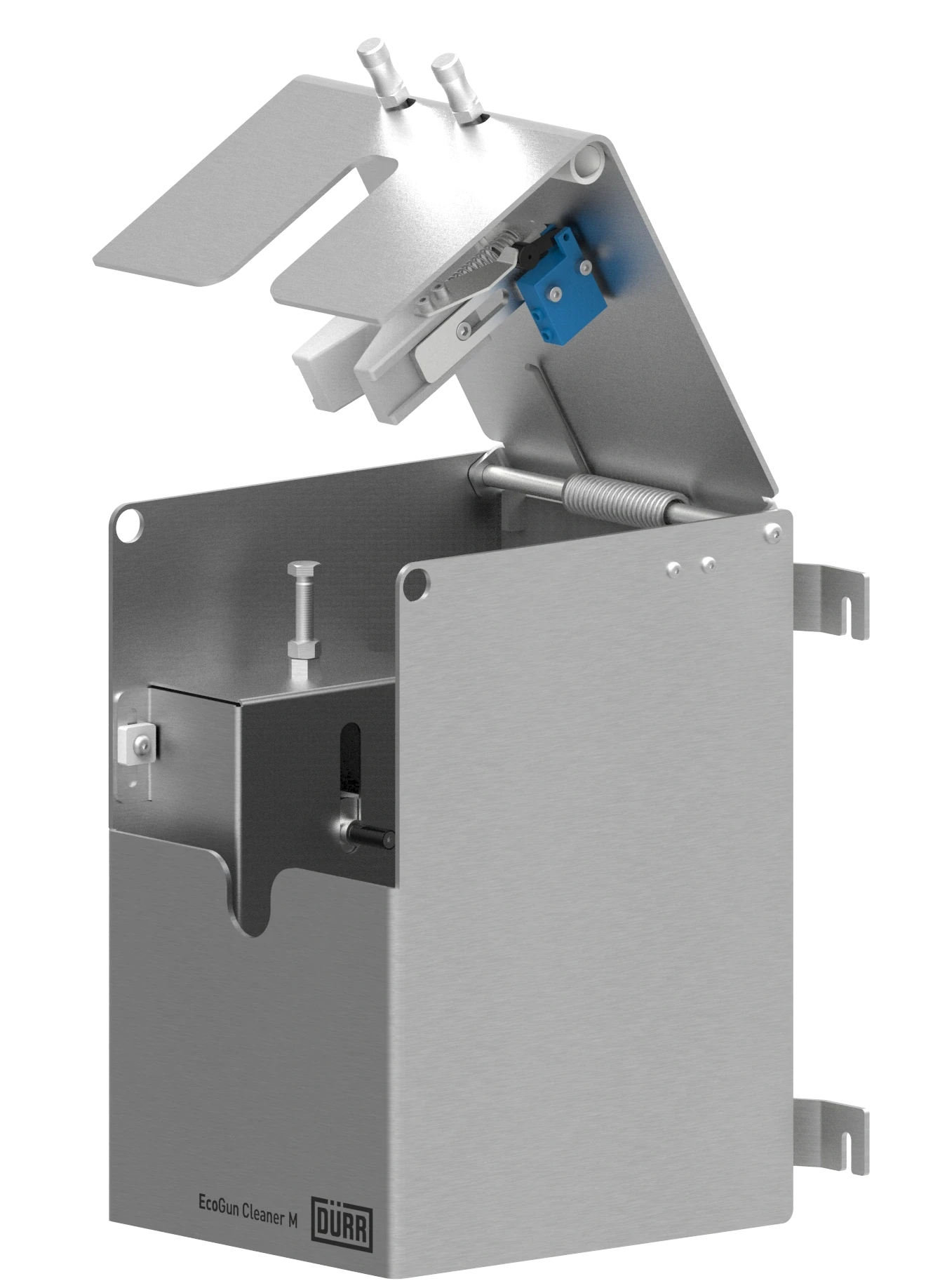

EcoGun Cleaner M

The EcoGun Cleaner M is a cleaning device for automatic cleaning of conventional and electrostatic manual spray guns with a pneumatic trigger for the manual gun release. It is suitable for solvent and water-based multi-component paints and a maximum pressure of 200 bar. As part of the EcoDose 2K electronic mixing system, direct control with pot time control is possible.

EcoGun CapCleaner

EcoGun CapCleaner is an efficient and quick solution to perform cleaning in an automatic painting process. The set of nozzles for solvent and air flushing provide reliable cleaning of the air cap. This ensures long lasting high quality performance in application processes. In comparison to brush-based cleaning devices, the EcoGun CapCleaner is not negatively affected by drying paint, as there is no direct contact with the brush or other components.

EcoPaintJet Cleaner

EcoPaintJet Cleaner is an efficient and quick solution to perform cleaning in an automatic painting process. The set of nozzles for solvent and air flushing provide reliable cleaning of the nozzle plate of the EcoPaintJet applicator. This ensures long lasting high quality performance in application processes.

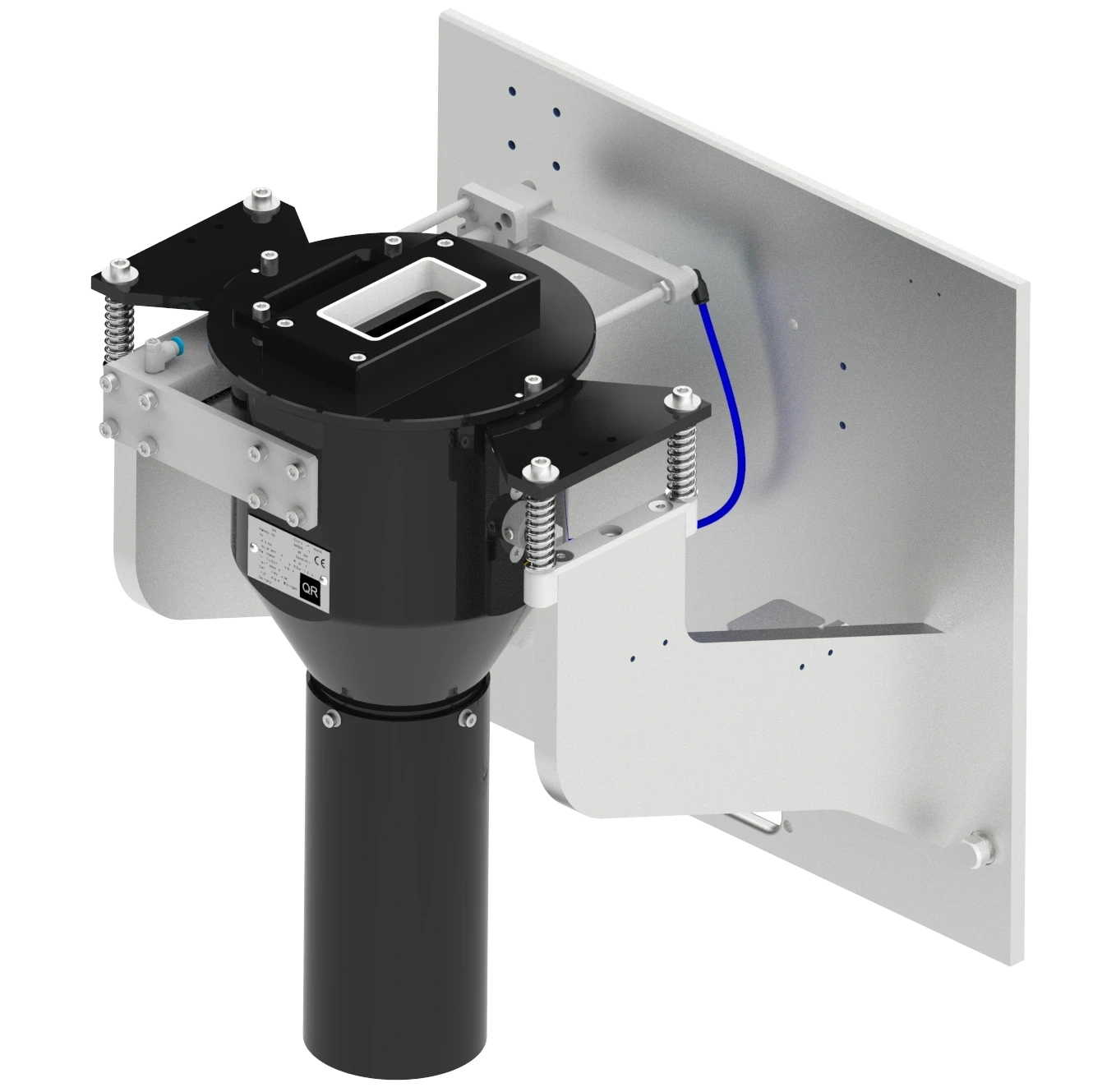

EcoBell PurgeBox

With the EcoBell PurgeBox, Dürr supplies an environmentally friendly collecting system for purge processes of EcoBell rotary atomizers. The EcoBell PurgeBox is used in automated paint shops and complements the EcoBell Cleaner D2 when 2-component paints are applied. In contrast to 1-component paints, 2-component media cannot be purged into the collecting pipe via the integrated return of the atomizer. They must instead be discharged to the front via the atomizer. With Dürr's innovative purging system, the residual paint from the 2-component atomizer is no longer directed into a collection funnel. VOCs regularly escape during this purging process into the spray booth. The EcoBell PurgeBox, on the other hand, catches all media that are created during short rinsing, color change rinsing, or color pressing.

The bell cup of the rotary atomizer moves directly into the box and flushes all media into the box. Inside the box there are special filter mats which let the air escape to the outside and at the same time collect the paint residues. The flushing medium flows off downwards and can be easily disposed of via a collecting pipe without additional flushing. In contrast to the funnel solution, there is no need to rinse the disposal line completely. The filter mats can be disposed of after use.

With the box, which can be easily integrated into the grating and is therefore also suitable for interior painting zones, up to 60 % less VOC is emitted during the purging process. In combination with Dürr's EcoRPC control technology, both the EcoBell Cleaner D2 and the EcoBell PurgeBox also offer the highest level of protection against high-voltage flashovers.

Your advantages with the EcoBell PurgeBox:

- All media are collected during short rinsing, color change rinsing, or color pressing

- Reduction of VOC emissions in the paint booth by up to 60 %

- Purging of disposal lines is no longer necessary

- Easy disposal of filter mats

- Particularly environmentally friendly

- Reduces the contamination of the spray booth due to color changes

- In combination with EcoRPC highest protection against high voltage flashovers