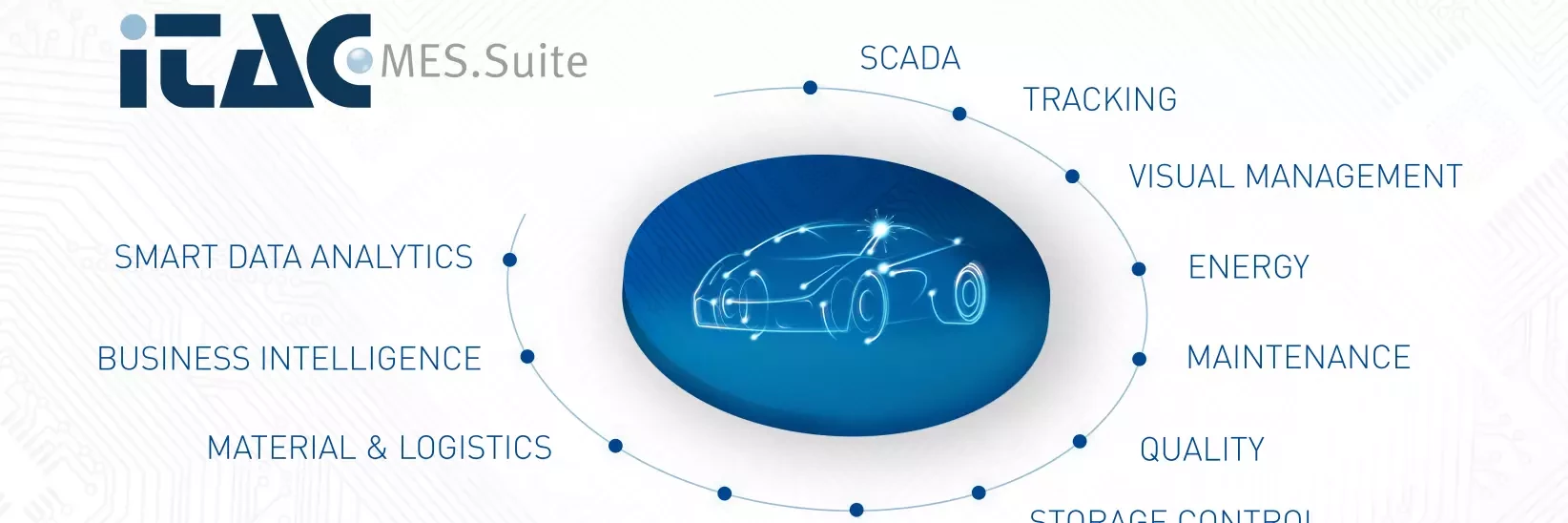

The iTAC.MES.Suite jointly developed by Dürr and its software subsidiary iTAC is based on modern software architecture and can be adapted to different production control requirements in the automotive, electrical, and component industries (tier 1). Users select the desired modules to receive a tailored solution for their entire production chain. As an agile MES with optimal release capability, the iTAC.MES.Suite forms the backbone for end-to-end networked and digitized processes in production and enables connections to modern IIoT solutions such as the ADAMOS platform.

New functionalities have been added to the proven modules, e.g. SCADA, stock control, vehicle tracking as well as energy and quality management, for controlling automotive production. This includes business intelligence and traceability for detailed product tracking. As a state-of-the-art system, the iTAC.MES.Suite also includes a comprehensive order planning module.

All the functions can be clearly visualized on screens. The iTAC.MES.Suite offers a comprehensive analysis of all plant parameters, and therefore forms the basis for Industry 4.0 applications. A cloud connection makes it possible to combine data from different production facilities across a plant and evaluate it using Dürr Smart Data Analytics. Processes and key performance indicators can thus be tracked in real time. The insights obtained can be used in a targeted manner to optimize the production workflows.

Data acquisition and storage with the iTAC.MES.Suite guarantees comprehensive traceability of all production processes. The future-oriented software architecture improves production monitoring, efficiency, and quality. To ensure that all data is kept within the company, the iTAC.MES.Suite offers maximum IT security: Dürr uses software technologies that provide protection against the latest attack scenarios and are updated regularly. These work with security measures on the customer side – e.g. firewalls and separation of office and production networks – to maximize security. For the customer, the fail-safe system offers a wide range of functions with high scalability. The flexible program structure permits individual combination and fast availability of the functional modules as well as easy software releases.

The iTAC.MES.Suite opens up a new dimension in the management of plants and production data. It is a cornerstone of the digital@DÜRR strategy, with which Dürr supports its customers in the digital networking of production.

The Dürr support teams in Bietigheim-Bissingen and other locations will continue to support existing installations of EcoEMOS, the predecessor of the iTAC.MES.Suite, both around the clock and around the world.

Dürr will present the iTAC.MES.Suite at the Hannover Messe at the “Smart Electronic Factory” stand (D26) in hall 7.