PAN- DUR 的玻璃元件采用强化安全玻璃(ESG),用于超市常见大型冷藏设备,如:墙上货架、橱柜或柜台,以保护内部存放的各种食品。 为了遮盖玻璃和制冷设备边缘不美观的粘合和密封接缝,PAN-DUR还采用了不透明装饰条。之前,喷涂该装饰条往往采用丝网印刷工艺,因而每次变换颜色、尺寸或设计,都需要更换新的丝网或模板,造成了浪费。

更灵活,更降本

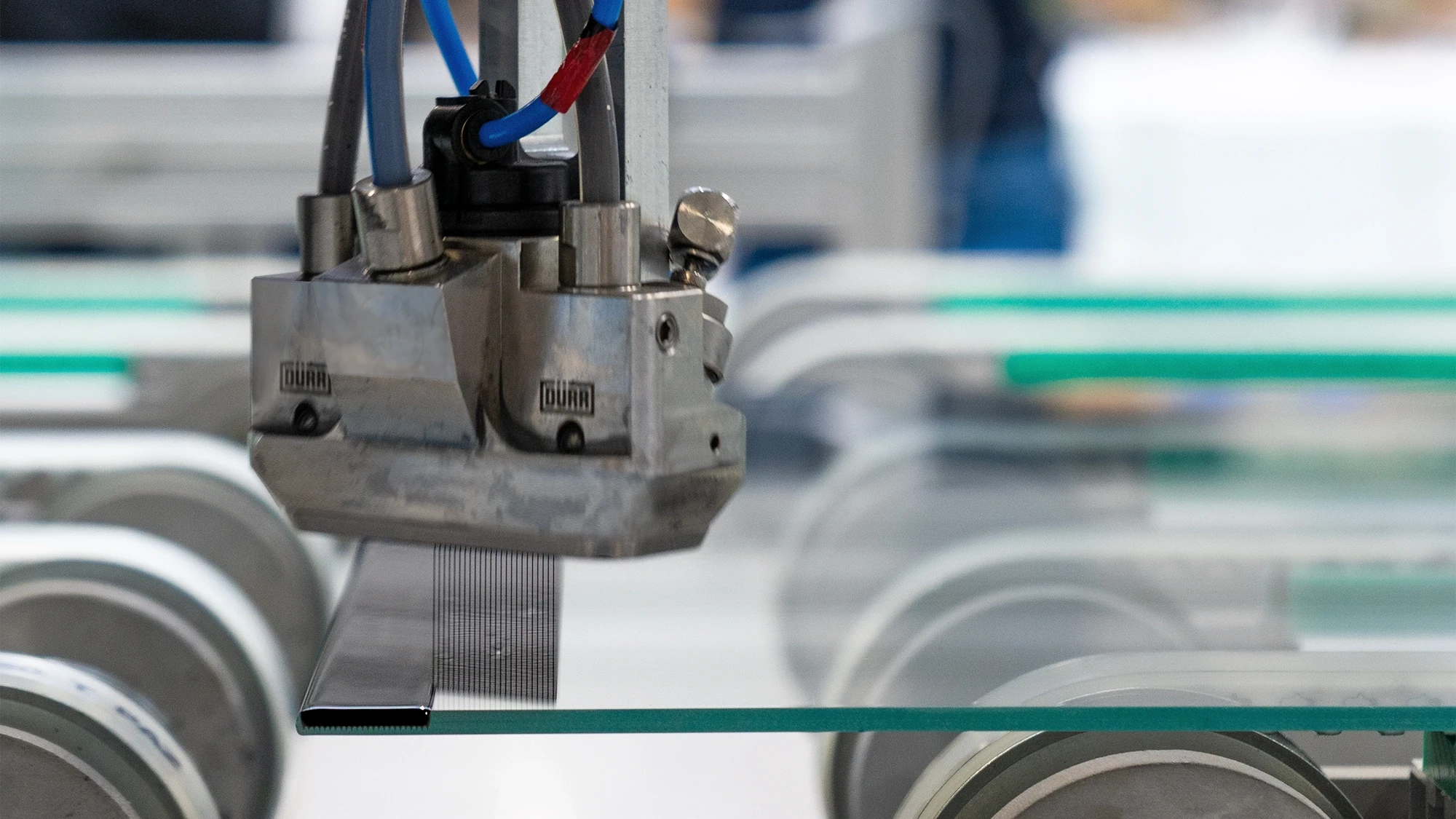

杜尔EcoPaintJet喷涂应用装置可实现高清晰度无过喷的边缘喷涂,这使得PAN- DUR 简化了复杂的丝网印刷工艺,从而提高生产的灵活性和速度,同时降低喷涂成本。在进行玻璃元件上不透明装饰条的喷涂时,PAN- DUR只需对每个轮廓进行简单编程,无需预先遮蔽玻璃表面,就能在相应的预定义区域上喷涂所需颜色,省去了复杂昂贵的单个模板制作,也无需占用宝贵的空间来存储模板。

一站式全套工艺技术

杜尔不仅为PAN- DUR 提供喷涂应用装置,还提供了从料桶中提取涂料到向喷涂机供应涂料的所有工艺技术。安装的系统包括 Fluid Board 流体盘、喷涂应用装置清洁器和 EcoAUC 控制单元。PAN- DUR开发了多轴接头,用于安装EcoPaintJet 可旋转且高度可调的喷涂应用装置,使其与自身工艺技术无缝集成。“将杜尔的工艺技术与我们的系统接口相连之后,实施过程顺利无比,”PAN- DUR 电气和自动化技术开发主管 Jens Verhoef 解释道。最大的挑战是找到适合在玻璃表面使用的涂料。专业涂料公司 Votteler 是 PAN- DUR 的长期合作伙伴,也参与了开发工作。项目经理 Uwe Schmidt 解释道:“给玻璃表面上漆极具挑战性,不仅需要专门开发的涂料,且涂料的流变特性、遮盖力和颗粒分布都要能完全匹配系统,并能兼容其他基材。因此,我们进行了多轮实验,终于找到合适的涂料。”

其他潜在工业应用

EcoPaintJet 还可用于其他工业领域,例如:木材工业、窗户或厨房建造以及铁路车辆喷涂领域。“各领域随处都有将直条纹喷涂于平整表面的需要,而目前这种喷涂方式仍需要遮蔽。因此,我们收到了许多来自不同行业的咨询” , 杜尔欧洲工业销售团队负责人 Fabian Schilt 表示。该系统之所以在应用拓展方面极具吸引力,还因为其具有另一项优势:所有组件均可集成到现有生产系统中。