Solutions that connect: Dürr delivers battery gluing application technologies for EV companies

Demand for electric vehicles is booming. A lightweight, durable battery is at the heart of each one. Dürr offers innovative methods for gluing to maximize the lifespan of every battery and keep vehicles on the road longer, while also meeting strict quality and safety standards.

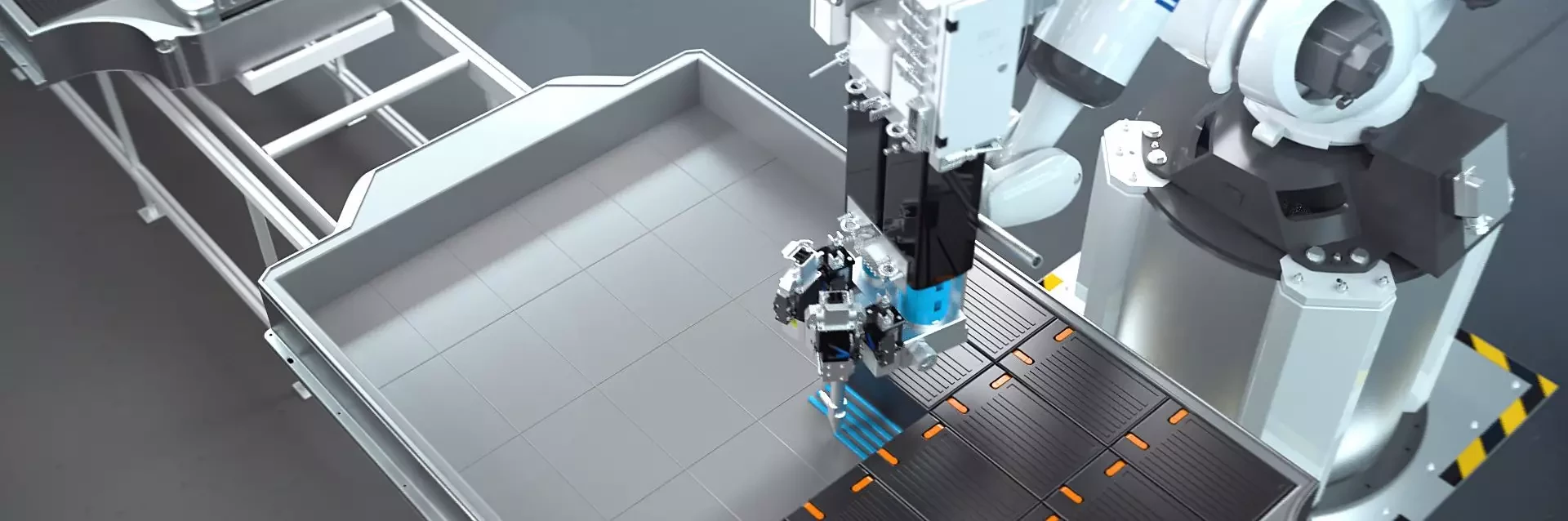

Dürr’s modular design of their battery gluing applications allows for flexibility in meeting different customer requirements and plant layouts. Whether you need prototype construction or large-volume processing, Dürr handles everything from individual components to overall systems for gluing applications.

Here are just a few of the products available for your battery gluing application needs:

- EcoRAM – A barrel pump that transports highly viscous materials (both heated and unheated) from the original barrels to the dosing device

- EcoHVMP – A modular, extendable control cabinet with standard components for controlling pumps and dispense applications

- EcoShot Meter – An electric piston dosing unit optimal for precise and dynamic high-viscosity applications

- EcoGun – An applicator that can be equipped with various nozzles for different tasks, ideal for highly viscous materials

Dürr’s highly trained staff will work in close coordination with you to optimize processes and technologies specifically adapted to your battery production requirements.

To learn more about how Dürr can help with your gluing applications, visit our website or contact us for more information.

Stay tuned for next week’s newsletter on Dürr’s body in white gluing capabilities.

Carl-Benz-Str. 34

74321 Bietigheim-Bissingen

Germany

26801 Northwestern Highway

48033 Southfield, MI

United States