ProFleet AGVs

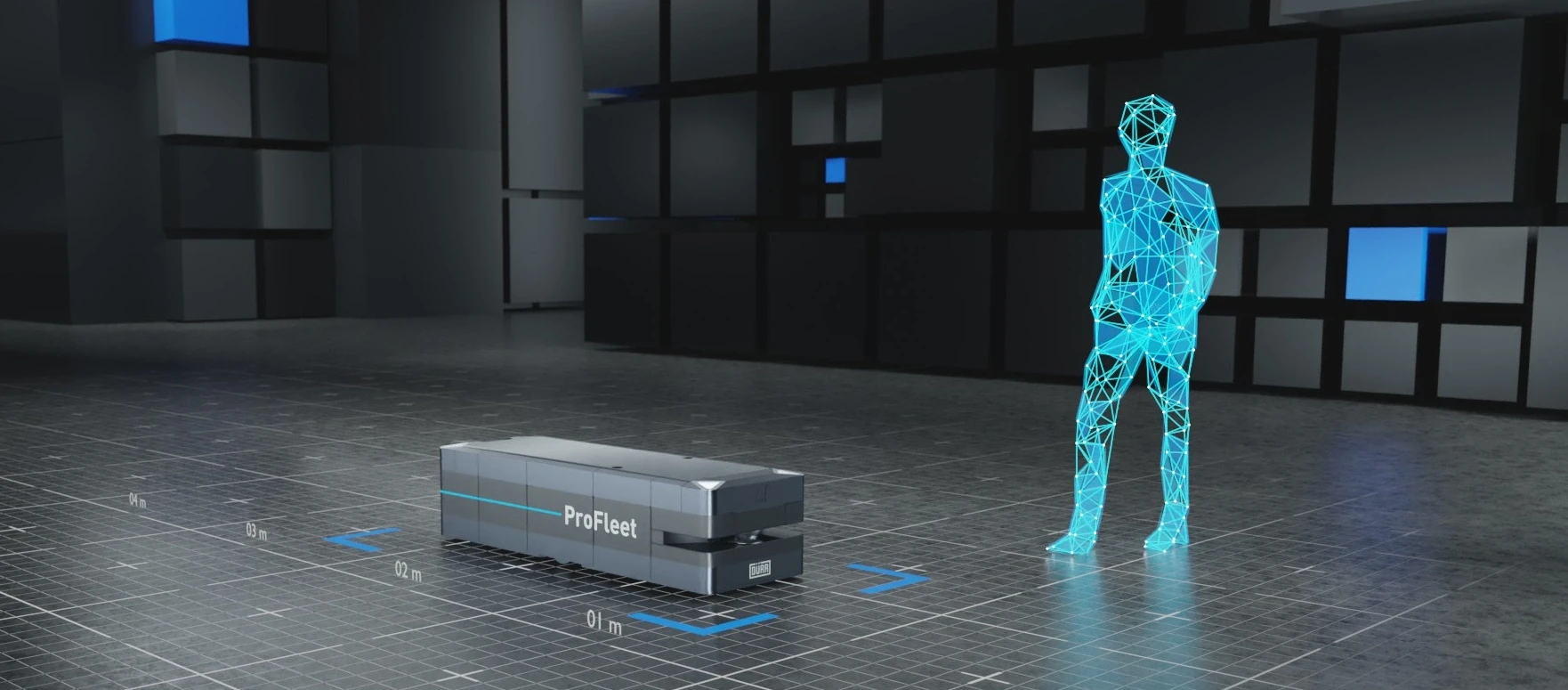

ProFleet 200: Compact and multifunctional

This is the smallest and lightest AGV produced by Dürr. It is ideal for trolley towing and transporting loads weighing up to 200 kg.

Equipped with tricycle or differential kinematics, it is ideal for achieving very high levels of performance in intralogistics or line feeding operations with an extremely low investment. It comes with a tug pin or a towing pin to manage one or more trolleys. The ProFleet 200 can interact with other systems such as the ProFleet solutions for kitting.

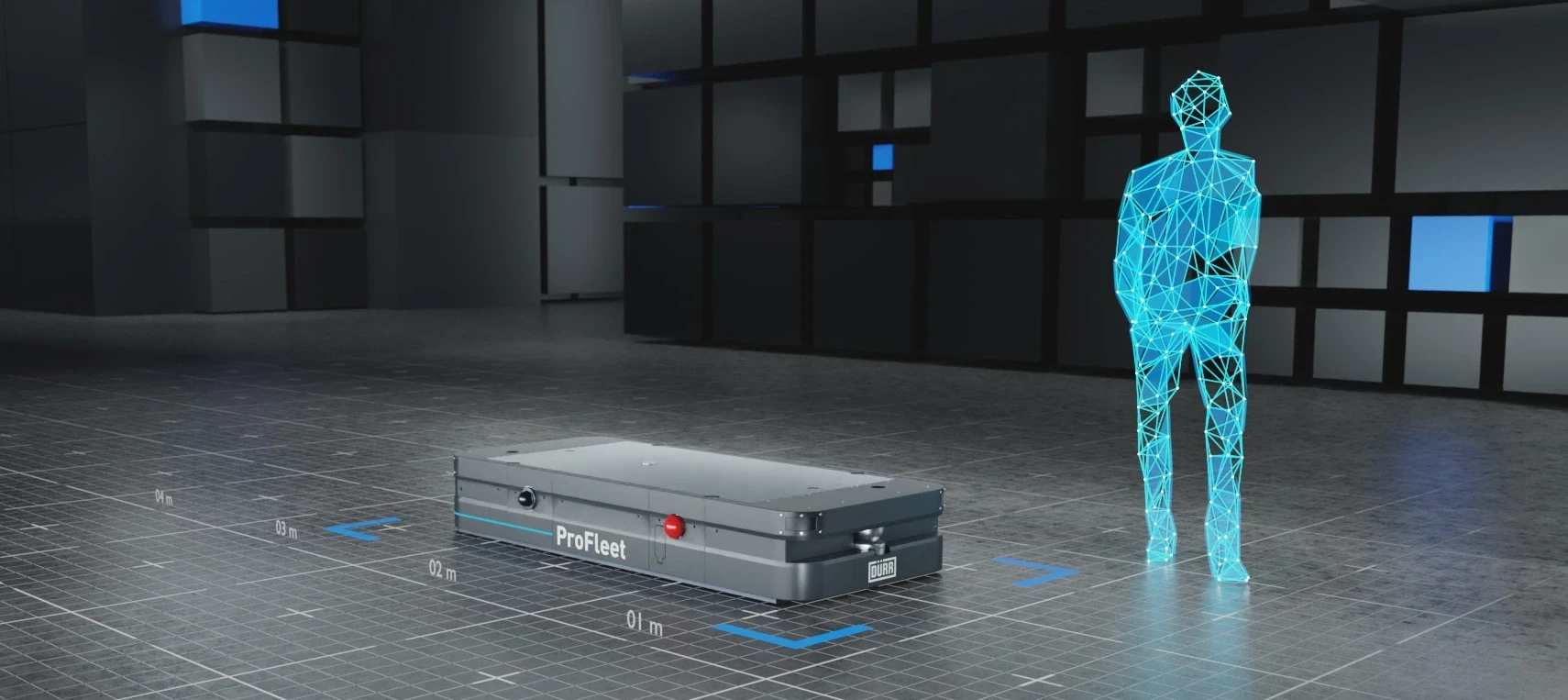

ProFleet 800: Small and agile

This is our compact, easy-to-handle AGV that moves drive trolleys and transports loads weighing up to 800 kg.

The system is particularly suitable for transporting small, lightweight components (for example doors, boards, devices, etc.) and for work zones where space is limited. It can be fitted with a towing pin for towing a trolley with a heavy load. The ProFleet 800 can also be used in combination with other conveyors to receive or deliver loads.

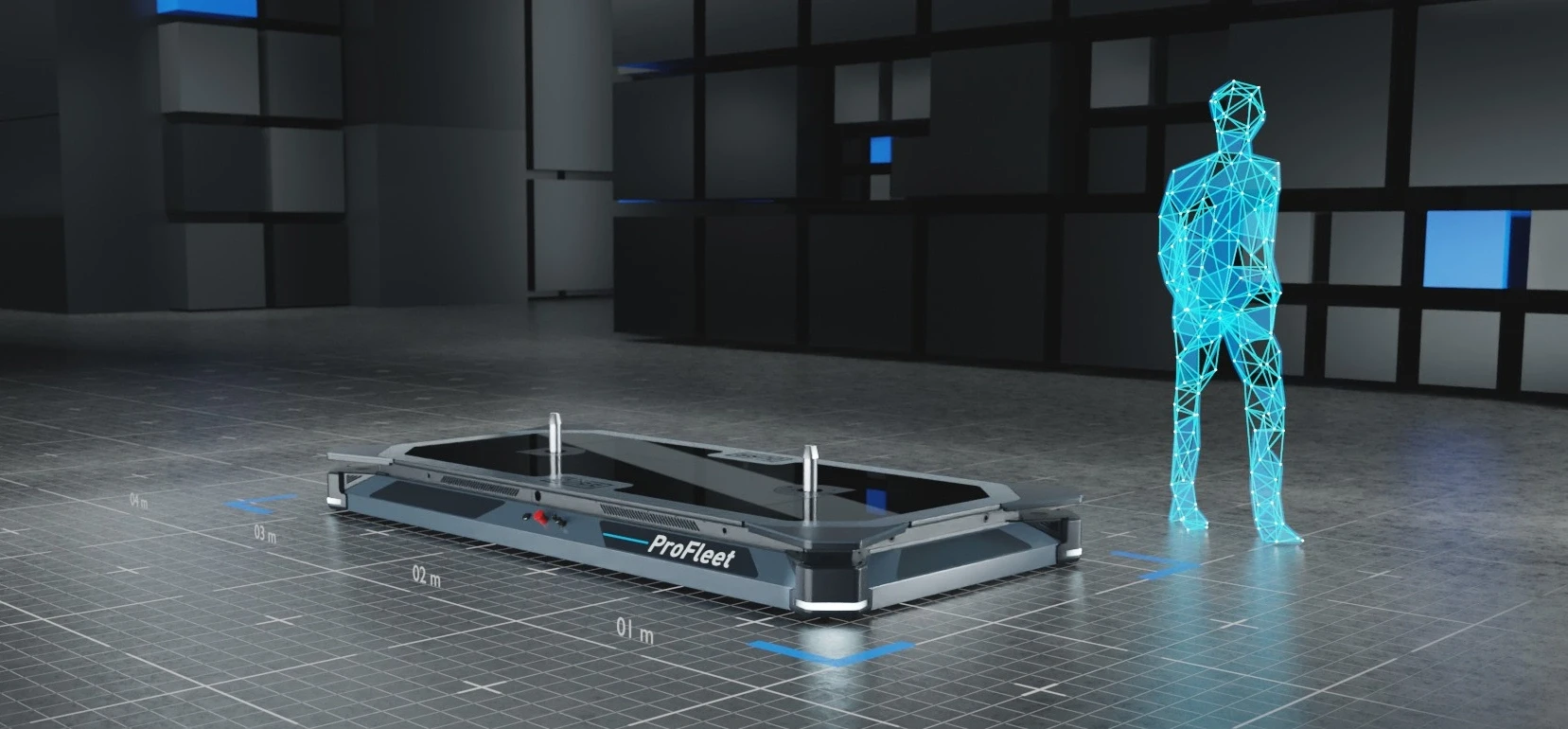

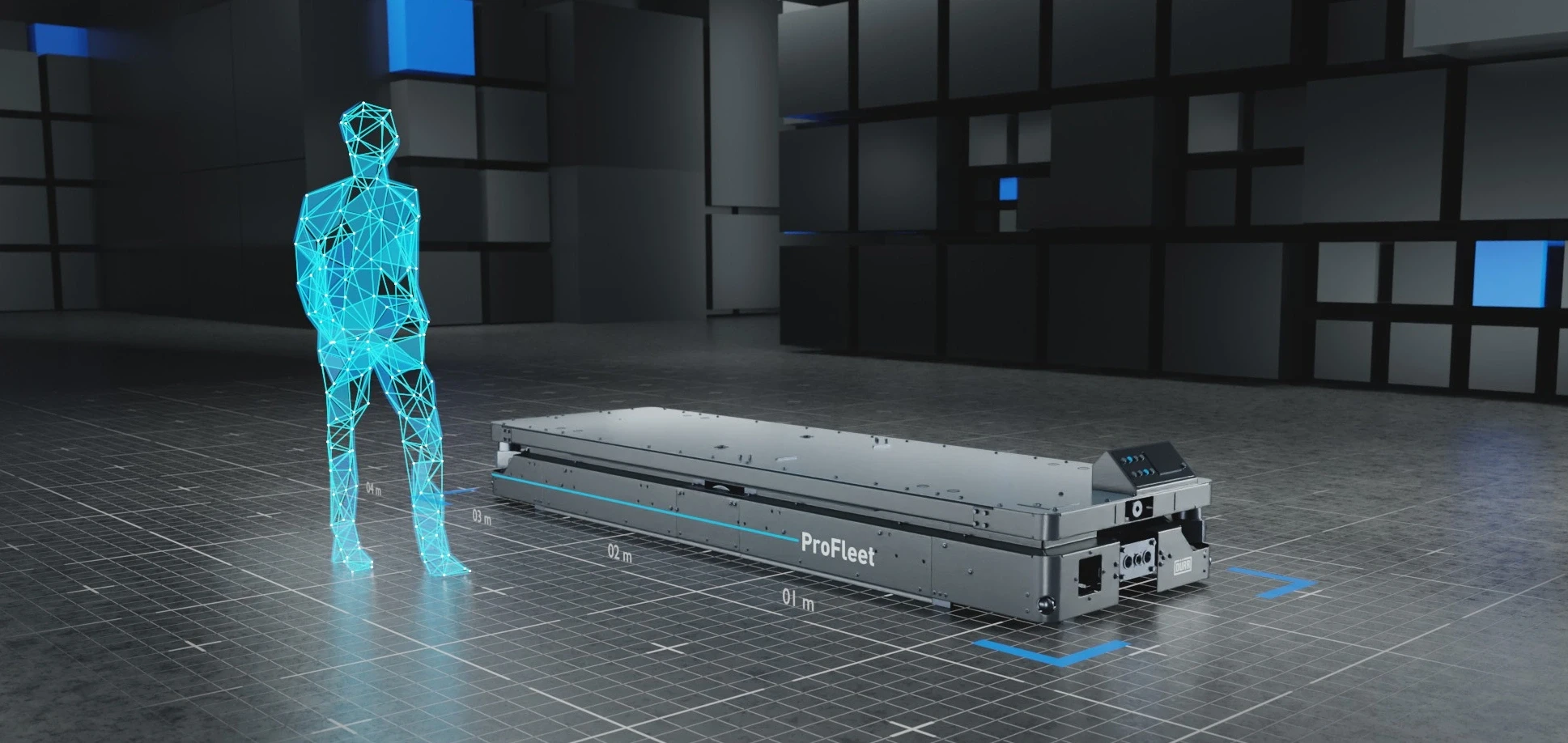

ProFleet 1000: Slender and nimble

This AGV is slender and highly agile and can be used for transporting medium-weight loads up to 1,000 kg.

Because of its low height, it provides the ideal ergonomic conditions for comfortable working. The AGV can be fully charged in a few minutes thanks to capacitors that can be charged quickly. The agile ProFleet 1000 is mainly used in paint shops where it transports vehicle bodies between different stages of the process. It is designed to interact perfectly with stationary units such as rollerbeds and work zones. It can also be used to transport other materials, including containers.

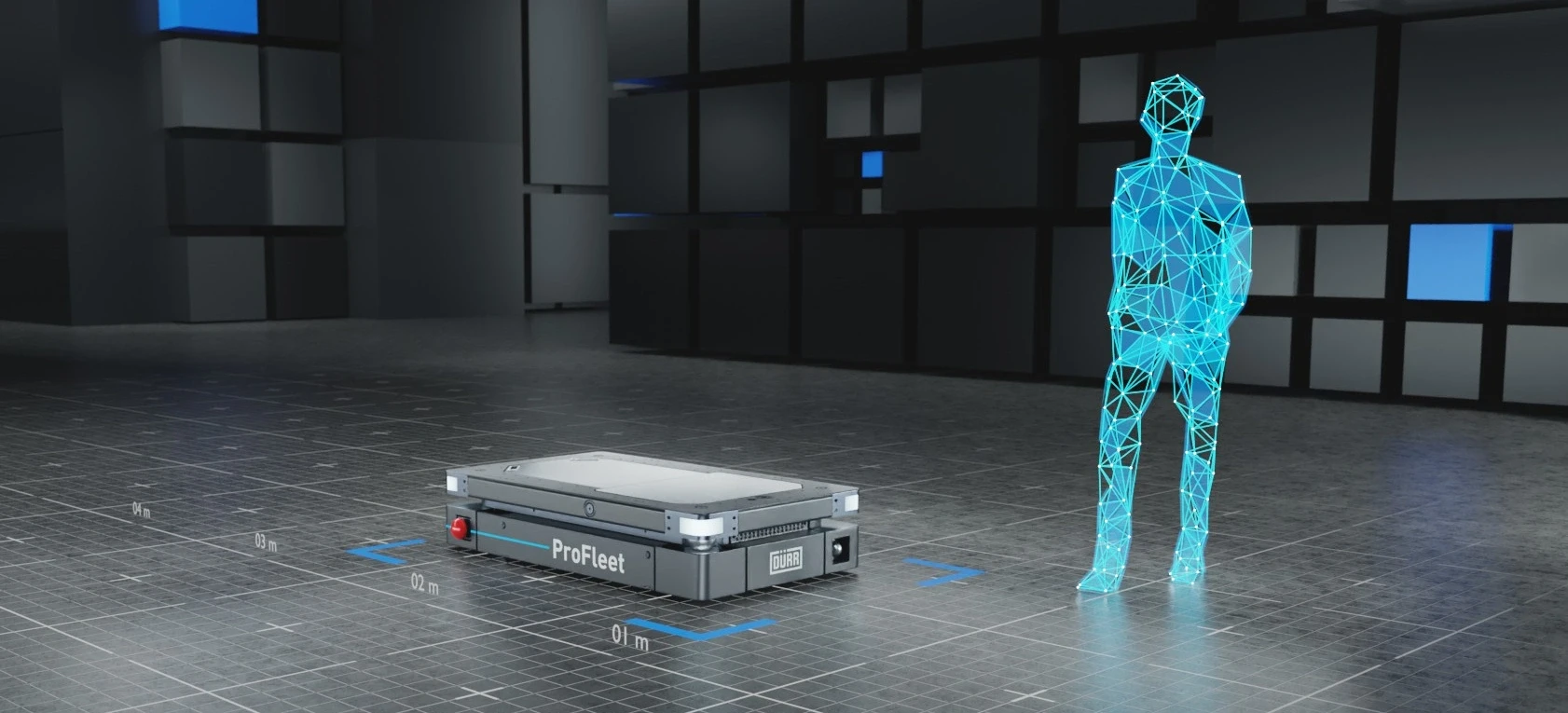

ProFleet 2000: Small and tough

The ProFleet 2000 has a highly compact design and can accommodate loads up to 2,000 kg.

It is ideal for transporting small and medium-weight components (for example, ICE and BEV powertrains, household appliances, etc.) and for use in areas where space is limited. Because of its compact design, it provides the ideal ergonomic conditions for comfortable working. A variety of accessories is available for the ProFleet 2000. With a cobot on board, for example, it is the perfect solution for automated kitting processes.

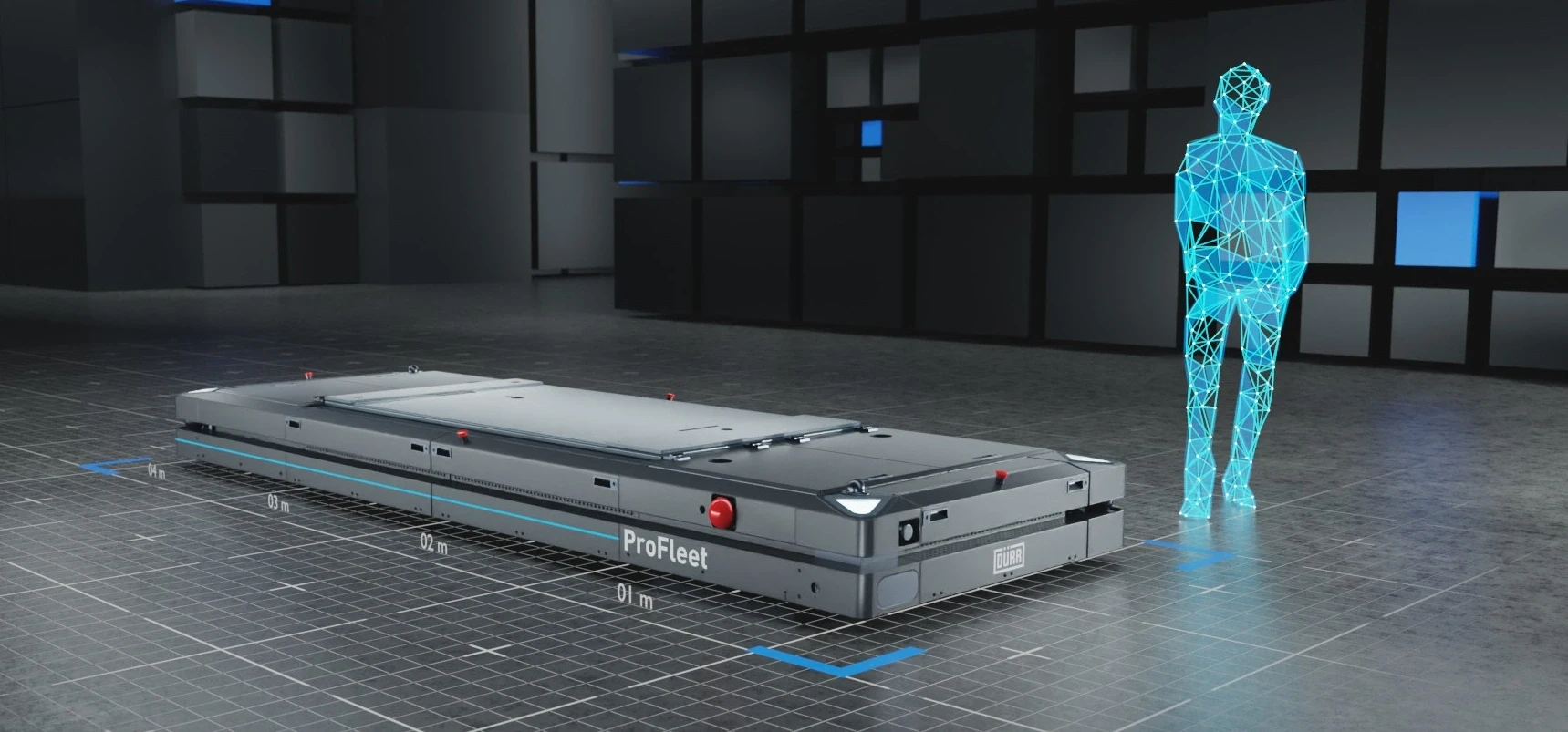

ProFleet 3000: Long and narrow

This Dürr AGV is used for transferring loads weighing up to 3,000 kg with a total length of 3,370 millimeters.

Particularly in a final assembly shop, it is highly suitable for the transfer of a tooling plate with mechanical parts or a battery. Its compact design makes it a reliable solution for assembly processes. With its wide range of accessories (for example, hydraulic clamping devices, engine stands, tilt tables), it is ideal for tasks such as preassembly. It can also be converted for combustion engine production lines now used to produce electric vehicles. If necessary, it can be used in continuous operation. It also allows work to be carried out while it is moving forward.

ProFleet 4200: Strong for heavy loads

The size of this automated guided vehicle provides a high level of stability when transporting and lifting loads weighing up to 4,200 kg.

The system is particularly designed for moving large and heavy components (for example, bulky reels of fabric or paper, complete vehicles, bodies, complete mechanics, etc.) and, in general, where the space dedicated to the AGV route is narrow or difficult maneuvers are needed to reach all workstations. In the version with omnidirectional kinematics, it is capable of extremely advanced maneuvers. The ProFleet 4200 can be equipped with a wide variety of accessories. With a scissor lift on board, the AGV guarantees ideal ergonomic working conditions. The AGV can be synchronized with other conveyors (such as overhead conveyors) for complex processes.

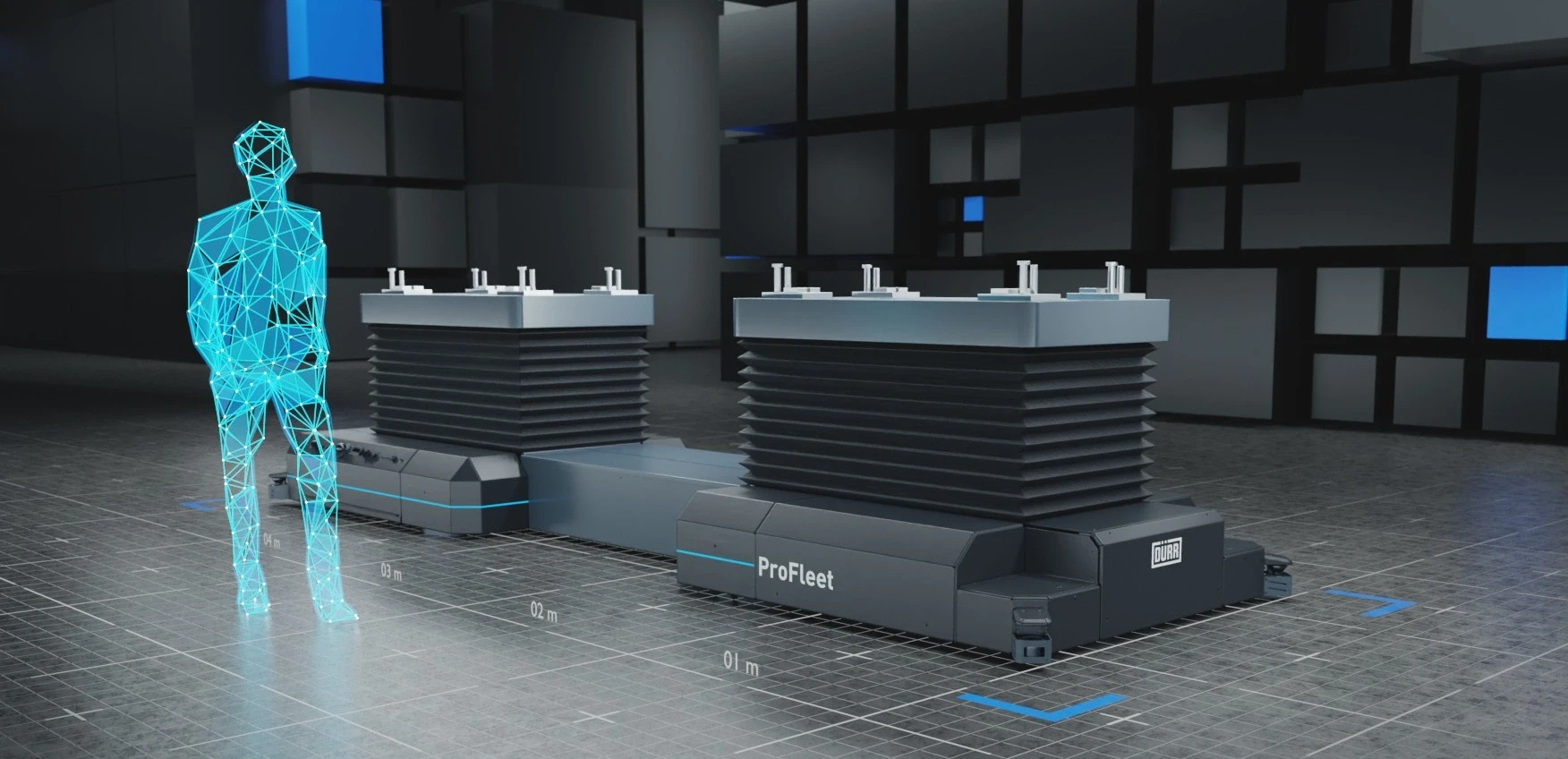

ProFleet X2 4200: Maximum performance to meet challenging requirements

This AGV is perfect for marriage processes without the need for operating personnel on board to intervene.

The ProFleet X2 4200 is designed especially for marriage final assembly. Its size allows it to handle even very large vehicle components. The ProFleet X2 4200 can be fitted with accessories, such as several lifting devices. This makes it possible to reach every part of the underbody of the vehicle body ergonomically and easily. It can also transport one or more tooling plates with mechanical components and batteries of the vehicle, guaranteeing ideal working conditions. The AGV can be synchronized with overhead conveyors for complex processes.

ProFleet X4 6000: Spacious enough to work on

Ideal for marriage processes with operating personnel on board.

The ProFleet X4 6000 is large enough to accommodate four operating personnel on board when in motion. This AGV uses special electromechanical lifting systems for coupling a drive train or a battery with the vehicle body. In addition, electrohydraulic systems bring the operating personnel to the right ergonomic position to intervene in the process. The AGV's lifting system has two lift tables that can carry a total payload of 5,000 kg (2,500 kg each). It is also equipped with the two platforms, each with a load-bearing capacity of 500 kg for transporting people.