Product Development Equipment and Services

To support your product and process development needs, Dürr offers small-scale roll-to-roll coating machines for customers who want to develop products and processes internally, and development services for those who want expert assistance with their development work.

LabCoater

The Dürr LabCoater is designed for product development and prototyping. It is modular, compact and simple to operate.

Reverse comma coater for short runs to develop new recipes.

Slot die coating for intermittent, lane or continuous patterns to support cell prototyping.

The process is easily scalable to production.

Development Center

Located in our De Pere, Wisconsin, USA, facility, the in-house pilot coating line offers mixing capabilities for the preparation of slurry mixtures, multiple coating methods, a three-zone flotation dryer that can be used with a wide range of substrates and tensions, a plasma and corona treater for foil substrates, and on-line coating thickness measurement and tracking.

The Dürr pilot coating line can help you conduct proprietary research and development, and test and optimize new or existing coatings, web materials and processes. The pilot coater facilities help avoid unnecessary overhead, capital equipment and start-up costs while developing new products. The facilities also provide the versatility and confidentiality needed for new product development, as well as the ability to produce prototype materials for further research, marketing, and quality testing.

Process engineers, R&D technicians, and analytic staff leverage their collective expertise to solve drying and coating challenges for an ever-increasing array of substrates.

Benchtop process tools

In-house drying lab: A bench-top system that captures complete drying characteristics of coated substrates from small-sized samples.

The system enables our process engineers to track rates of evaporation for water and organic solvents and to determine the drying time required to reach target solvent or moisture residuals in the product.

The drying lab is geared toward the early scale-up steps in formulation development, drying characterization, optimization, and troubleshooting.

Heat transfer stand: Used for thermal characterization of drying and curing nozzles over a wide range of application conditions. The capabilities include quantitative heat transfer coefficient characterization and qualitative analysis of drying conditions to prevent defects.

Parallel plate rheometer: Used to characterize the rheology of coating fluids to set up slot dies for optimum performance during coating trials.

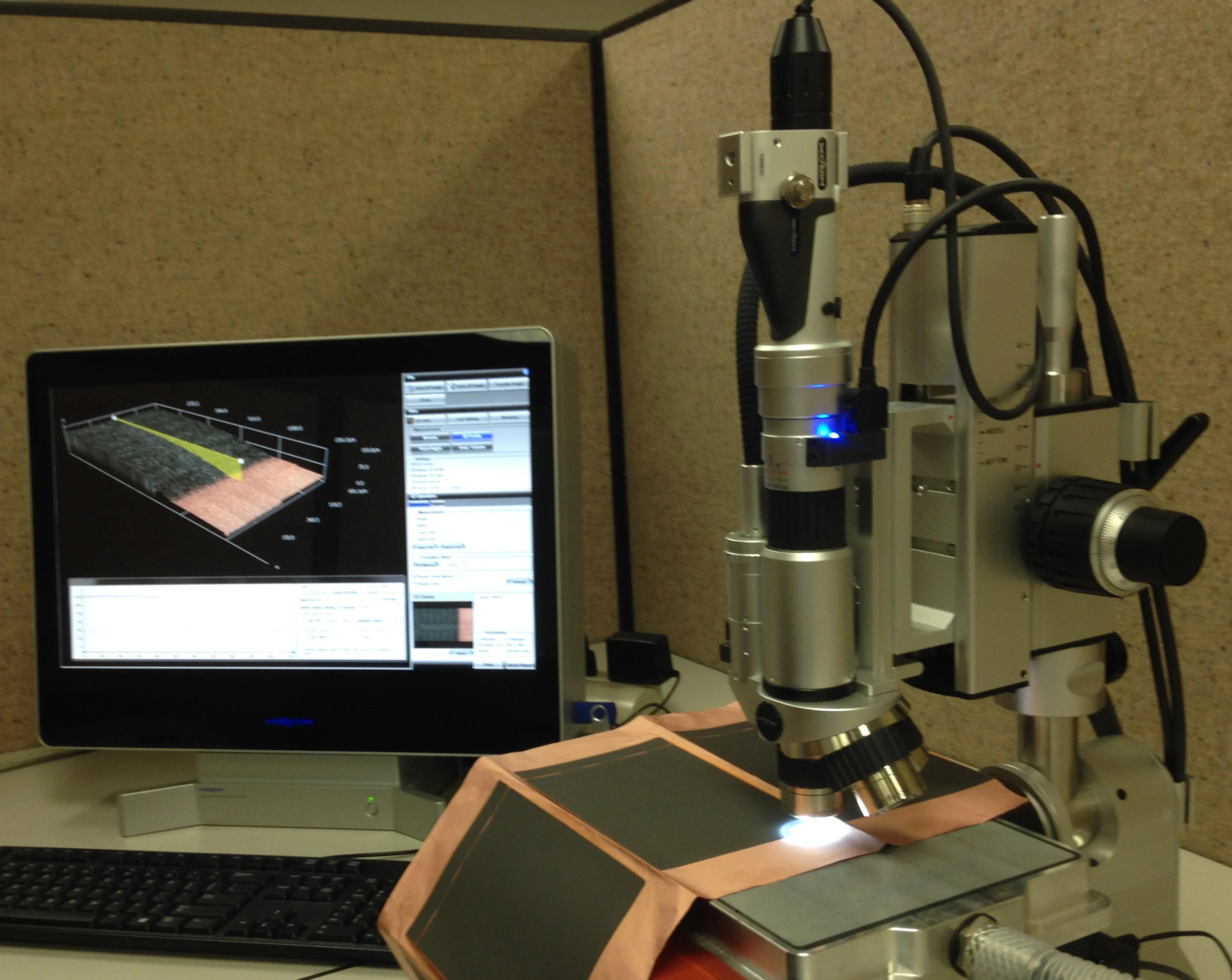

Hirox® Digital 3D microscope: Used for measuring the quality of coated samples, defect analysis, and visual characterization of 3D objects/samples (catalysts, media, etc.).