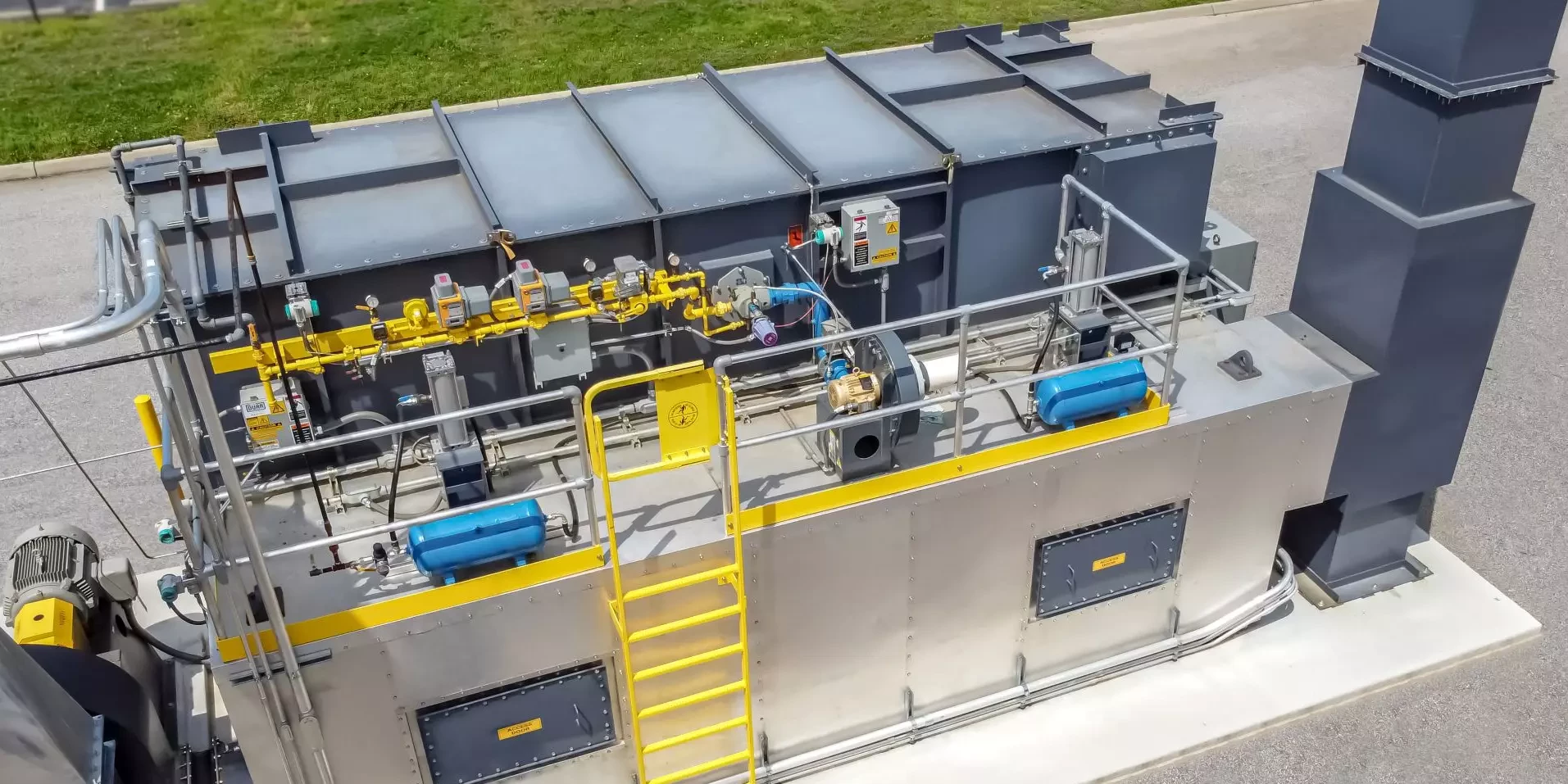

Oxi.X RM – Regenerative thermal oxidizer (RTO)

For low-flow process applications, the Oxi.X RM regenerative thermal oxidizer (RTO) redefines the economics of clean air compliance compared to other VOC control technologies typically deployed in high-flow process applications. The former name of the Oxi.X RM was Millennium®.

Oxi.X RM RTO Benefits

The Oxi.X RM RTO uses a cost-effective and robust ceramic heat-exchange media. The exceptionally low-resistance of the media minimizes pressure drop, which means smooth operation and reduced electrical operating costs for VOC abatement, managing hazardous air pollutants (HAPs), and odor control.

- Energy-efficient variable frequency drive (VFD)

- Thermal efficiencies up to 97%

- Low pressure drop ceramic media

- Simple, touch-screen controls

- Modem support

- Purge/idle makeup air damper

Oxi.X RM RTO Operating principle

The Oxi.X RM RTO system features integrated ductwork, individual poppet valves, and a unique, single-box configuration. These features save on both capital and installation costs. The compact, space-saving unit offers considerable installation flexibility. Systems for either indoor or outdoor placement are available, and the relatively light weight of the Oxi.X RM RTO easily permits rooftop installation.

Fast, Simple Installation

The system is preassembled, pre-wired, pre-piped, and pre-tested at the factory. All Oxi.X RM RTOs ship via commercial trucks. The installation and startup time is kept to a minimum, typically requiring less than one week. Turnkey installations are available.

Operational reliability

The Oxi.X RM RTO practically operates by itself. In standard configuration, the only moving parts are two reinforced poppet-style valves. An advanced electronic control system automatically tunes the system for high VOC destruction rates with maximum fuel efficiency. The system is engineered to deliver low maintenance costs.

Oxi.X RM RTO Application areas

The small, entrained volume of the Oxi.X RM RTO holds VOC puffs to a minimum. The standard system can achieve up to 98 percent VOC destruction, which is sufficient to meet most clean-air requirements. For higher cleanup rates, a VOC capture system is available. This option can be ordered as original equipment or field-installed at a later date.

Secondary Heat Recovery

Dürr offers secondary heat recovery for applications where higher solvent loading yields require more heat than what is needed to sustain oxidation. The recovered energy can be returned to process applications or used to reduce other plant energy requirements.

Oxi.X RM RTO Technical Specifications

This unique, compact system can meet the needs of a wide variety of industrial applications at flows extending to 15,000 SCFM (23,700 Nm3/hr). The Oxi.X RM RTO combines operating efficiency, destructive effectiveness and overall reliability with very affordable capital, installation and operating costs.

| Flow Capacity | Up to 15,000 SCFM (23,700 Nm³/h) | ||

| VOC Destruction Efficiency | Typically 98%-99% | ||

| Thermal Efficiency | Up to 97% | ||

| System Fan | Forced Draft w/VFD | ||

| Optional Secondary Heat Recovery | Yes | ||

| Heat Exchange Media | Ceramic |