Paint supply systems

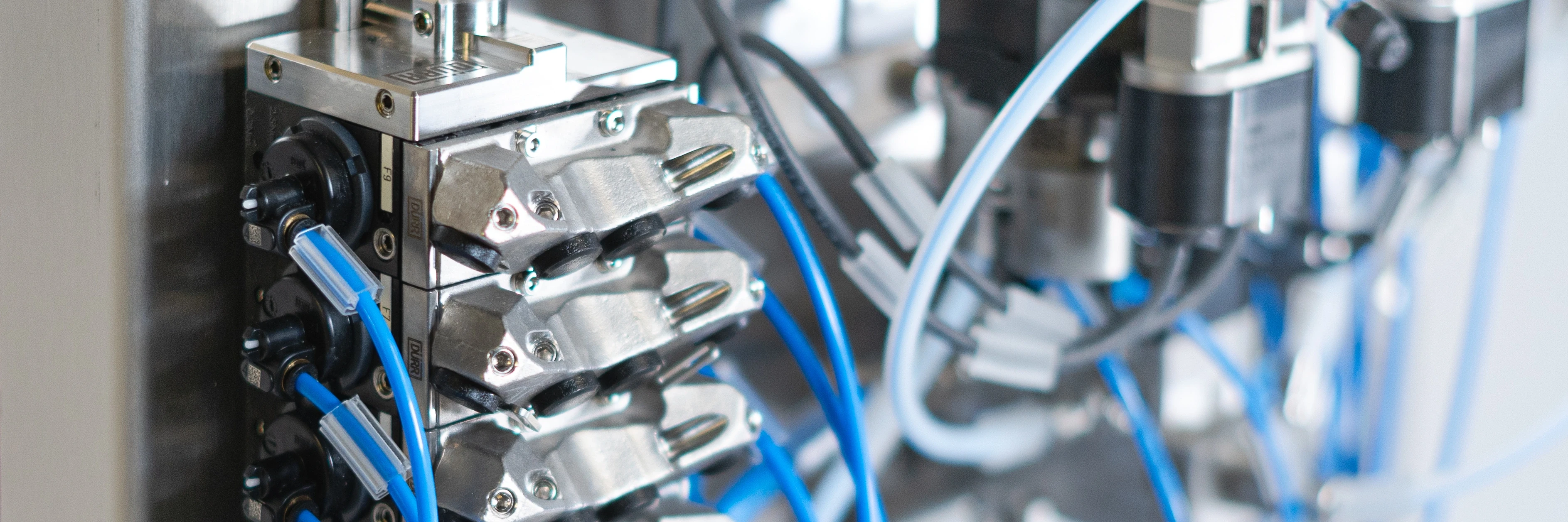

Fluidboard

The Fluid Board is a connection between control unit and applicator to quickly and easily create a complete concept consisting of control unit, dosing technology, flange package and applicator in the high quality that characterizes Dürr's technical solutions. It ensures high quality and simplifies the creation of the concept. The compact design of the fluid plate allows installation even in confined spaces and requires no assembly effort as it is delivered fully assembled. The EcoDocu facilitates the commissioning, operation and maintenance of the paint dosing and color change system.

In addition to color change technology with the EcoMCC and the EcoValve7 series of valves, the EcoPump9 GW is used for high-precision dosing and the compact EcoFlow controllers for flow control.

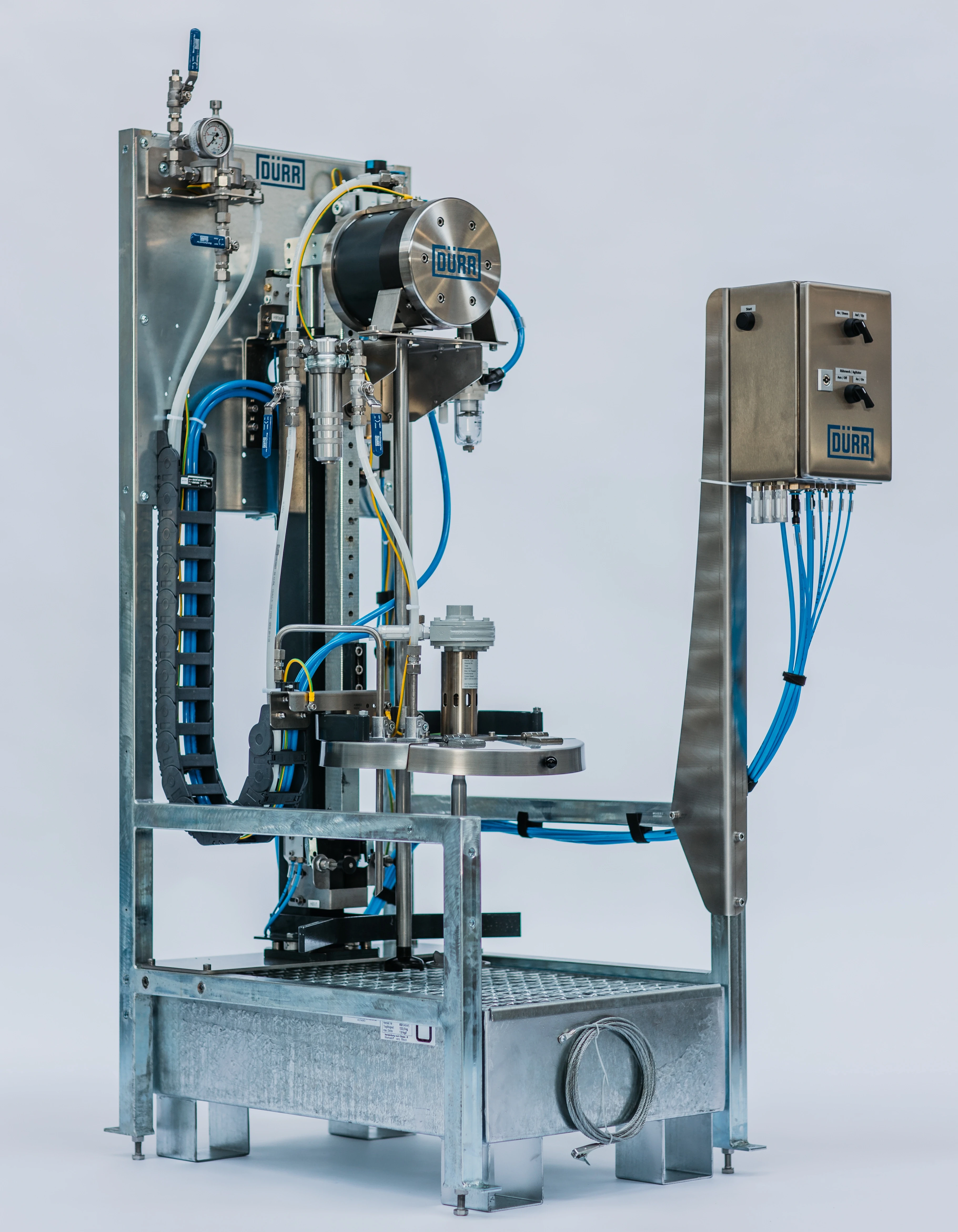

EcoSupply2 Core

EcoSupply2 Core is a modular paint supply station that integrates all the necessary components in one compact unit. This space-saving and easy-to-use system is ideal for all industrial applications where painting takes place in confined spaces. Material can be fed from hobbocks, pressure vessels or a flow cup, and a wide range of pumps, pressure regulators, filters, agitators, etc. are available. From engineering to assembly to commissioning, EcoSupply2 Core saves integrators and end users a lot of time because the pre-assembled complete package only needs to be put into operation on site and is certified for the European, American and Asian markets.

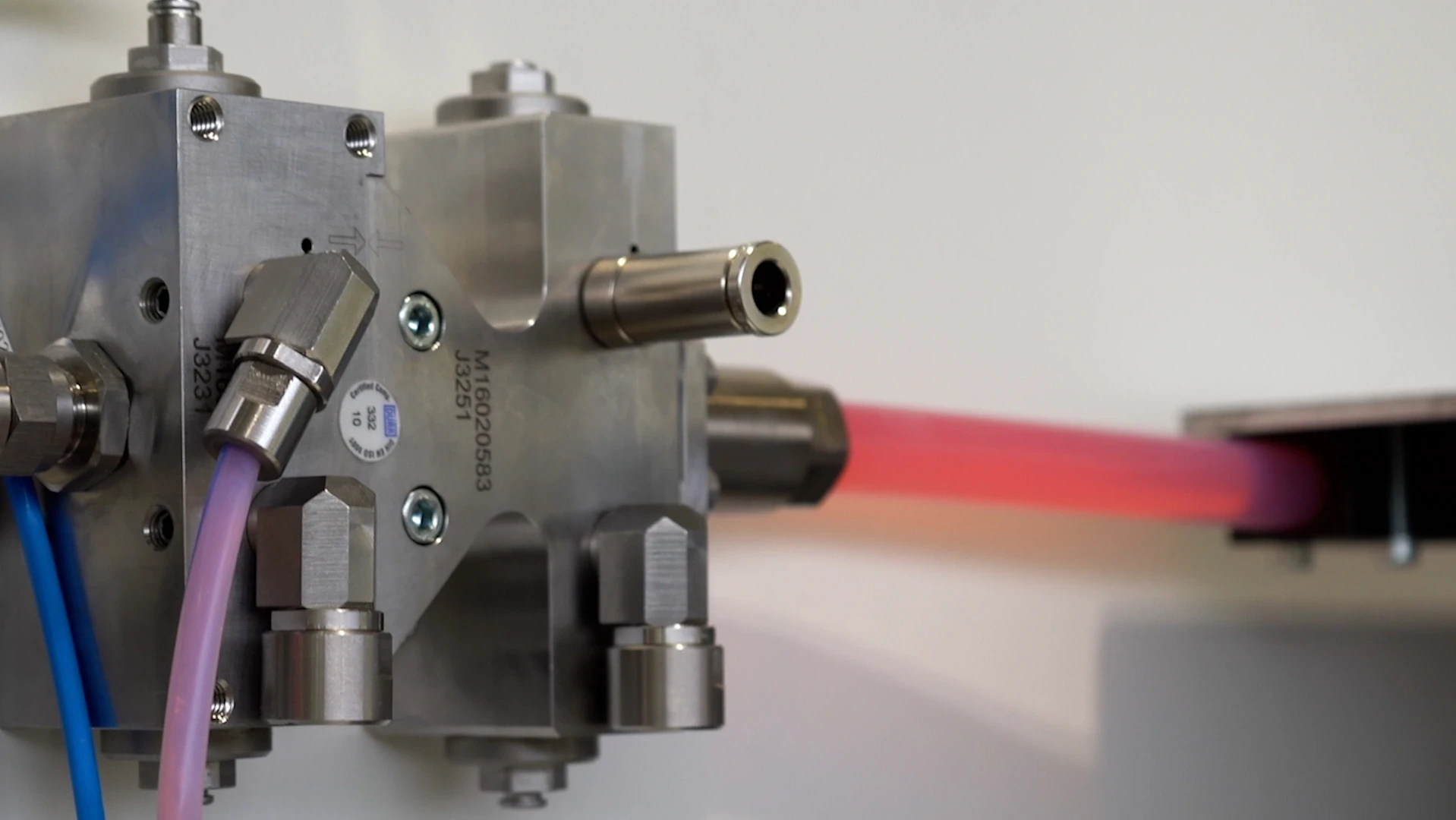

EcoSupply P Core

EcoSupply P Core is a modular paint delivery system with pigging technology. In conventional paint supply systems, the hoses are cleaned with detergent and compressed air before the next color is loaded. This increases the color change loss with the length and diameter of the hose between the color changer and the spray gun. To solve this problem, Dürr offers components that use a pig, a type of rubber plug, to clean the hoses. Since the pig can also push the paint back into the original container, paint losses can be significantly reduced. It also reduces the amount of detergent used. With multiple systems, one color can be applied to an already loaded hose while another hose is being prepared for the next color.