Around the world, statutory regulations are requiring plant operators to adhere to increasingly stringent limit values for volatile organic compounds (VOCs). In industrial painting, VOCs escape when changing color and during the associated flushing of the atomizers. To change paint, the channels inside the atomizer must be flushed before the new paint is pressed on. Regular exterior cleaning of the atomizer housing is also necessary so that no overspray can fall from the atomizer onto the body. The development of the EcoBell Cleaner D2 with integrated droplet separator has enabled VOC emissions to be reduced by 94 percent compared with the previous model, on the one hand through the 90 percent reduction in flushing agent consumption achieved through the elimination of a cleaning pass and on the other hand through the collection of the spent media.

Flushing funnels have many disadvantages

In the case of materials with just one component, such as are typically used for primer and base coats, the paint in the atomizer channels can be fed into the manifold via a return and collected. This means that only very little media has to be flushed forwards out of the atomizer. In the EcoBell Cleaner D2, this flushing takes place in parallel with the cleaning of the atomizer in cycle time. “For two-component paints, this kind of clean solution was not available on the market up to now because these materials pose special challenges for the flushing process,” reports Sandra Schlichenmaier, R&D engineer at Dürr. Since two-component paints have a short curing time, they must be fully drained forwards out of the atomizer. Up to now, the paint has either been fed directly into the booth or into a funnel that is flushed at regular intervals. The flushing of the funnel produces a dynamic spray cloud, from which a lot of VOCs escape. In addition, the funnel must be regularly flushed with sludge thinners so that the two-component material does not clog the funnel – this also introduces VOCs into the booth.

Easy disposal

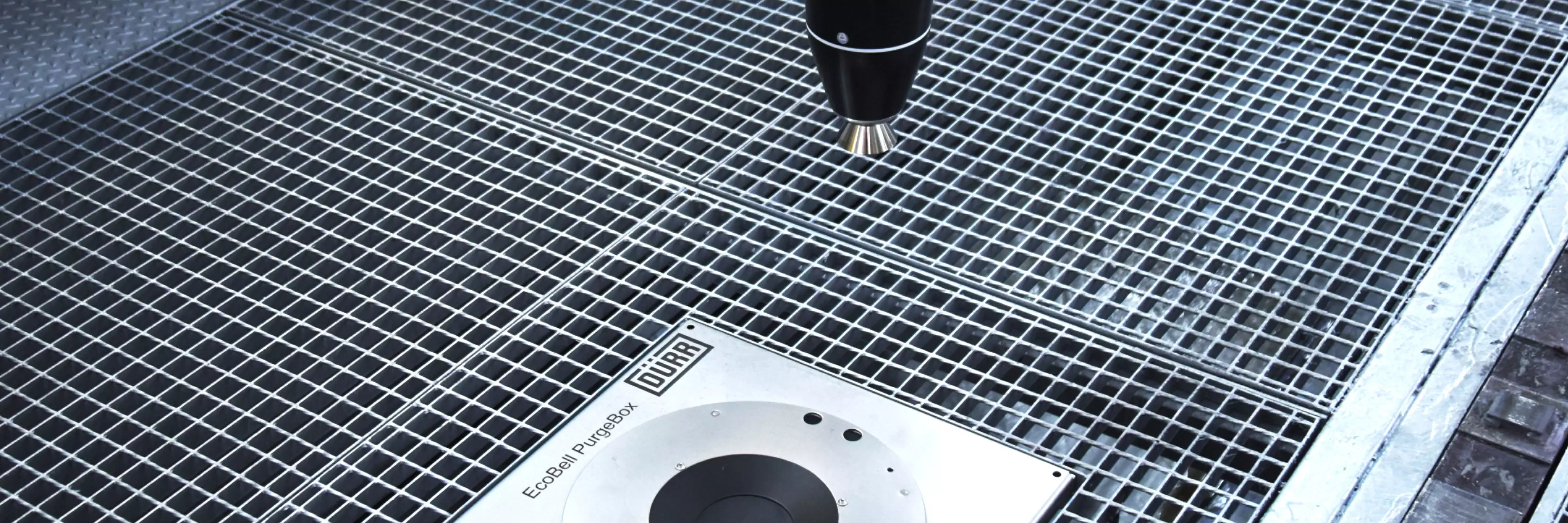

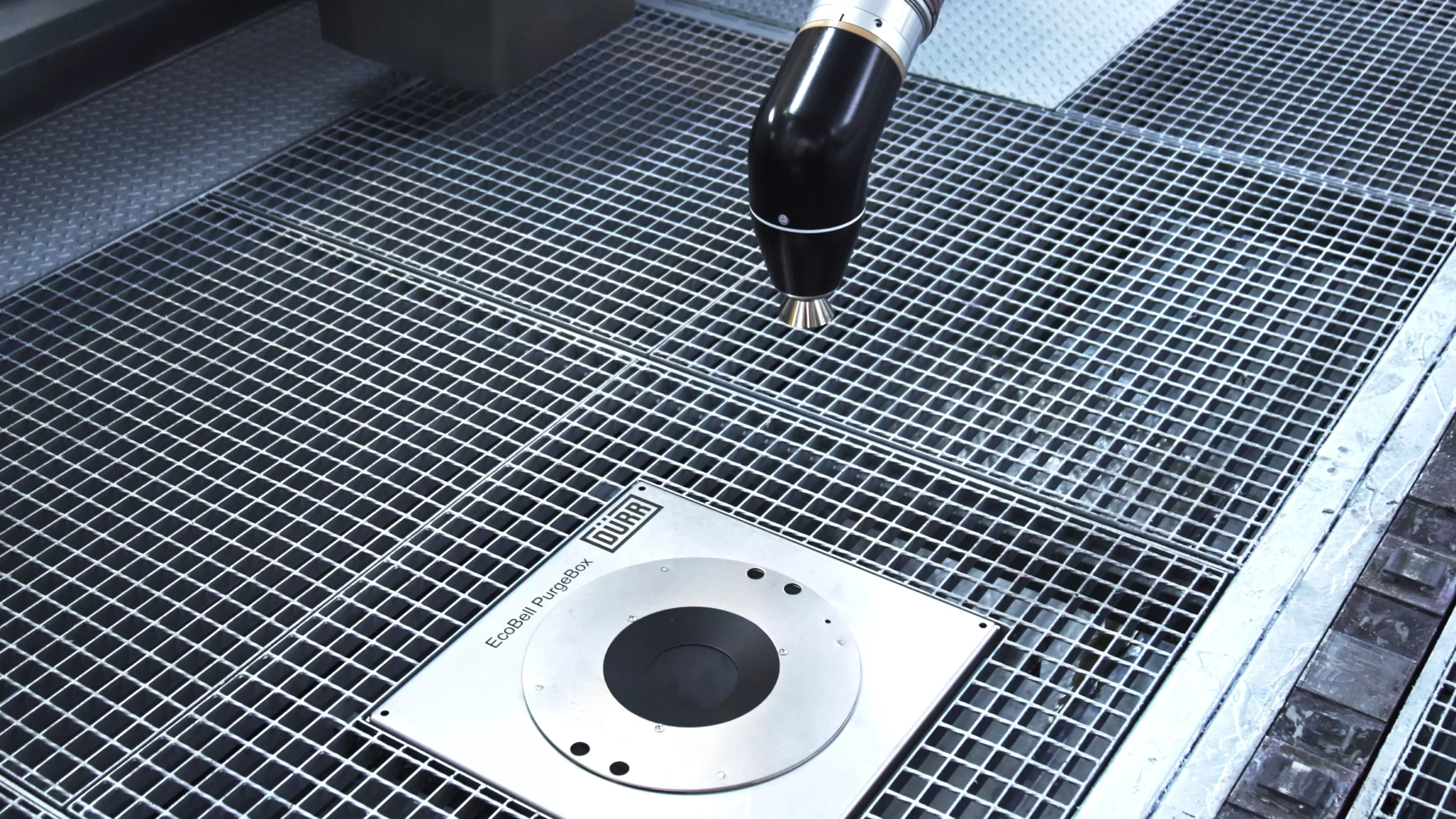

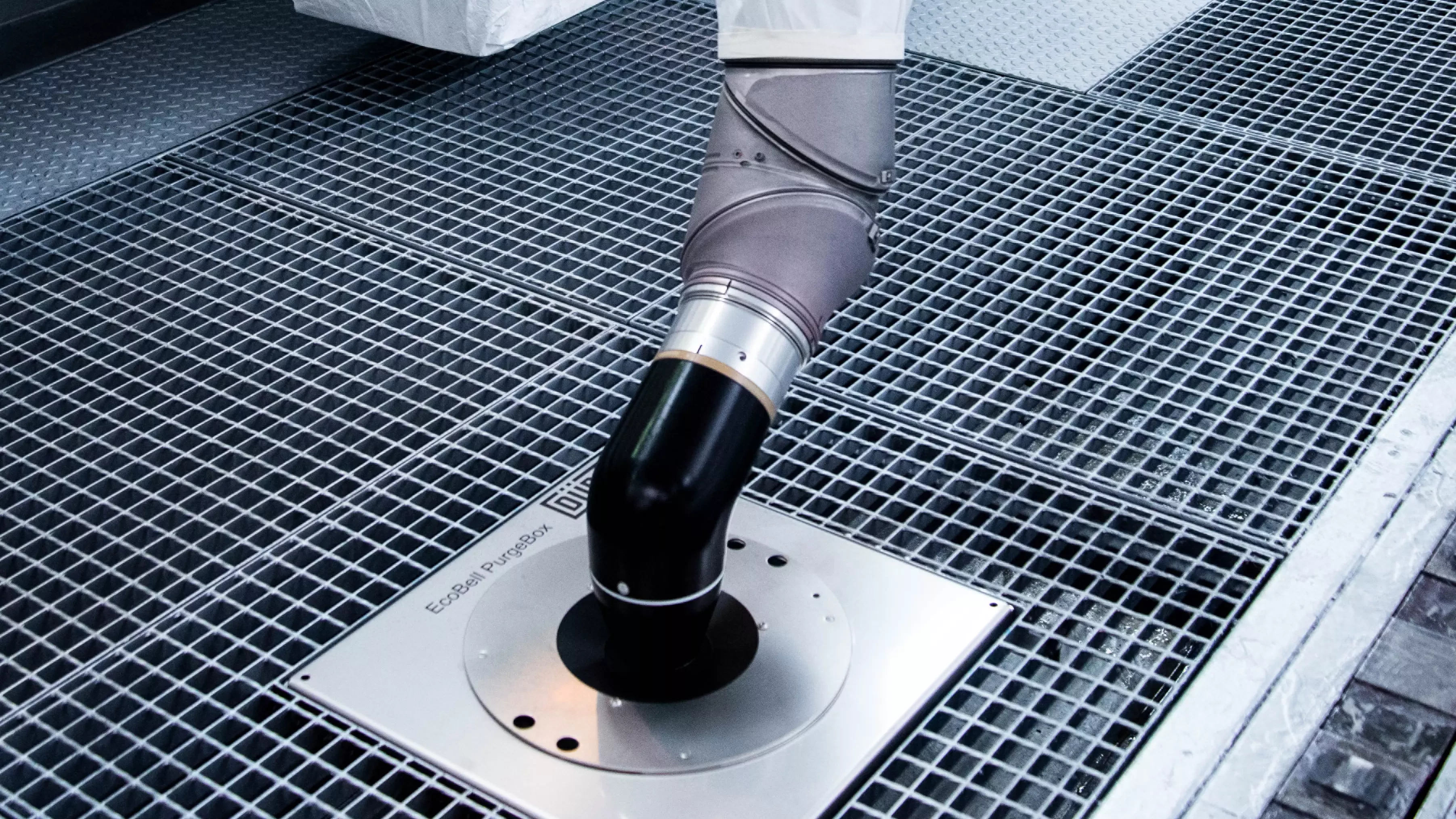

The newly developed EcoBell PurgeBox is a system that replaces the funnel solution entirely and significantly reduces the VOC load in the booth. Instead, the atomizer moves into the box. The special filter mats in the box collect the majority of the paint, the air escapes to the side, the almost pure flushing medium flows downwards and can be disposed of with ease via a manifold line that requires no additional flushing. The filters are simply discarded as residual waste after their lifetime. “In two-component zones, it will be possible to significantly reduce VOC emmissions by means of flushing and cleaning processes if an EcoBell Cleaner D2 is combined with an EcoBell PurgeBox instead of a funnel,” says Sandra Schlichenmaier.

Protection zone against high-voltage flashovers

Another unique feature is the high level of protection offered by the EcoBell PurgeBox and also the EcoBell Cleaner D2 in combination with Dürr’s EcoRPC control technology. A virtual protection zone ensures that the atomizer cannot come into contact with any grounded components while it is under high voltage. The software switches off the system if the protection zone is violated to prevent flashover on combustible paints.