Enhancing environmental sustainability: Dürr installs RTO at SAPIN

In the face of growing environmental concerns, industries worldwide are seeking innovative solutions to reduce their environmental footprint. In Saudi Arabia, a significant step towards sustainable industrial practices has been achieved with the installation of a regenerative thermal oxidizer (RTO) by Dürr at SAPIN, a leading name in the metal packaging industry. This installation marks a major advance in reducing harmful emissions and underscores the commitment to environmental protection.

About SAPIN (Saudi Arabian Packaging Industry WLL)

Headquartered in Dammam, SAPIN is a prominent player in the Gulf region's packaging sector, best known for its production of metal cans. With a history of innovation, SAPIN has consistently evolved to meet the demands of a competitive market, recently expanding its operations to include innovative packaging solutions. The Saudi Arabian packaging industry has seen substantial growth, increasing from 39.3 billion units in 2018 to 44.5 billion units in 2023, with further growth expected. SAPIN's proactive approach to sustainability and innovation positions the company as a leader in the region's packaging landscape.

The need for emission control

The metal printing processes at SAPIN release volatile organic compounds (VOCs), which pose significant environmental and health risks. VOCs contribute to air pollution and climate change, necessitating effective emission control technologies. The installation of the RTO by Dürr addresses these concerns by significantly reducing VOC emissions, aligning with global environmental goals and Saudi Arabia's Vision 2030 initiative for sustainable development.

About Dürr

The Dürr Group is one of the world's leading mechanical and plant engineering firms with outstanding expertise in the fields of automation and digitization. In the field of environmental technology, Dürr specializes in the development and production of advanced systems that efficiently manage exhaust gases and minimize energy consumption, while ensuring highly reliable operations. As one of the largest suppliers of emission control systems for the industry, Dürr provides comprehensive solutions and oversees projects from planning to implementation and maintenance. As a systems partner, Dürr combines its technological expertise with global reach to support customers worldwide.

Installation of the Regenerative Thermal Oxidizer (RTO)

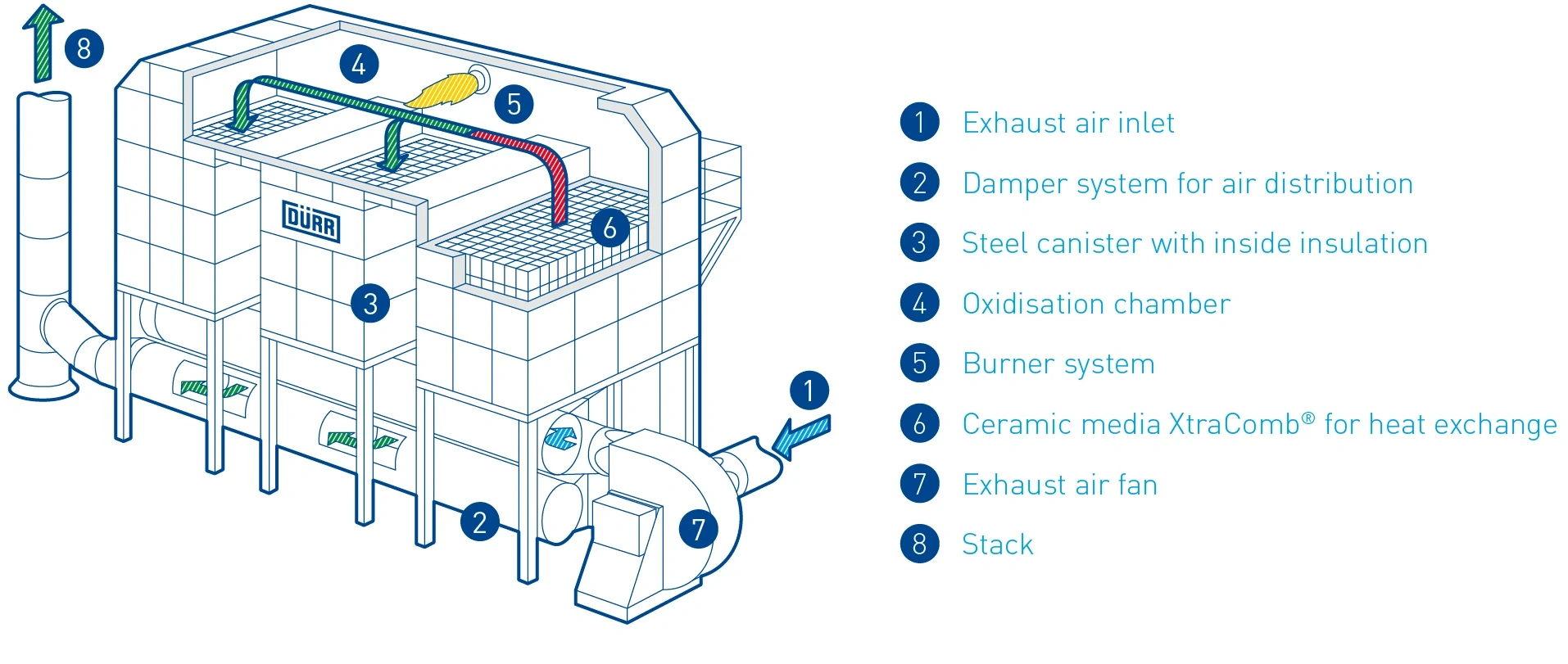

Dürr’s RTO technology Oxi.X RA is at the forefront of emissions control, designed to convert VOCs into harmless carbon dioxide and water vapor through high-temperature oxidation. The regenerative process involves capturing and reusing heat to preheat incoming air, drastically reducing energy consumption. This makes the RTO not only effective at reducing emissions but also highly energy-efficient, providing significant savings in operational costs. The system can operate in autothermal mode, minimizing the need for external energy sources, which enhances its sustainability credentials.

Benefits to SAPIN and the Environment

The RTO installation is a testament to SAPIN's commitment to sustainability and innovation. By reducing VOC emissions, SAPIN is contributing to cleaner air quality and a healthier environment. This initiative supports SAPIN's sustainability goals and sets a benchmark for the Saudi packaging industry, encouraging other companies to adopt similar technologies. The environmental benefits extend beyond SAPIN, contributing to global efforts in combating climate change and the promotion of industrial responsibility.