This four-day Open House featured dedicated topics showcasing advancements in automotive painting and final assembly systems, as well as innovations in painting, gluing, and environmental technology for various industries. Michael Baitinger, CEO of Dürr China, stated, "Innovation is not just a reflection on the past; it is a commitment to the future. We look forward to continuing our partnerships to create a greener, smarter, and more efficient production environment, and to embrace a brighter future." Dürr China, with nearly 1,200 employees, has delivered over 100 turnkey projects for vehicle painting and final assembly in China by the end of 2023, underscoring its engagement with the local economy. Dürr's ‘local for local’ approach ensures projects for China are planned locally, with dedicated local contacts. The Dürr subsidiary has made significant investments, generating CNY 3.3 billion.

Insights into the paint shop of the future

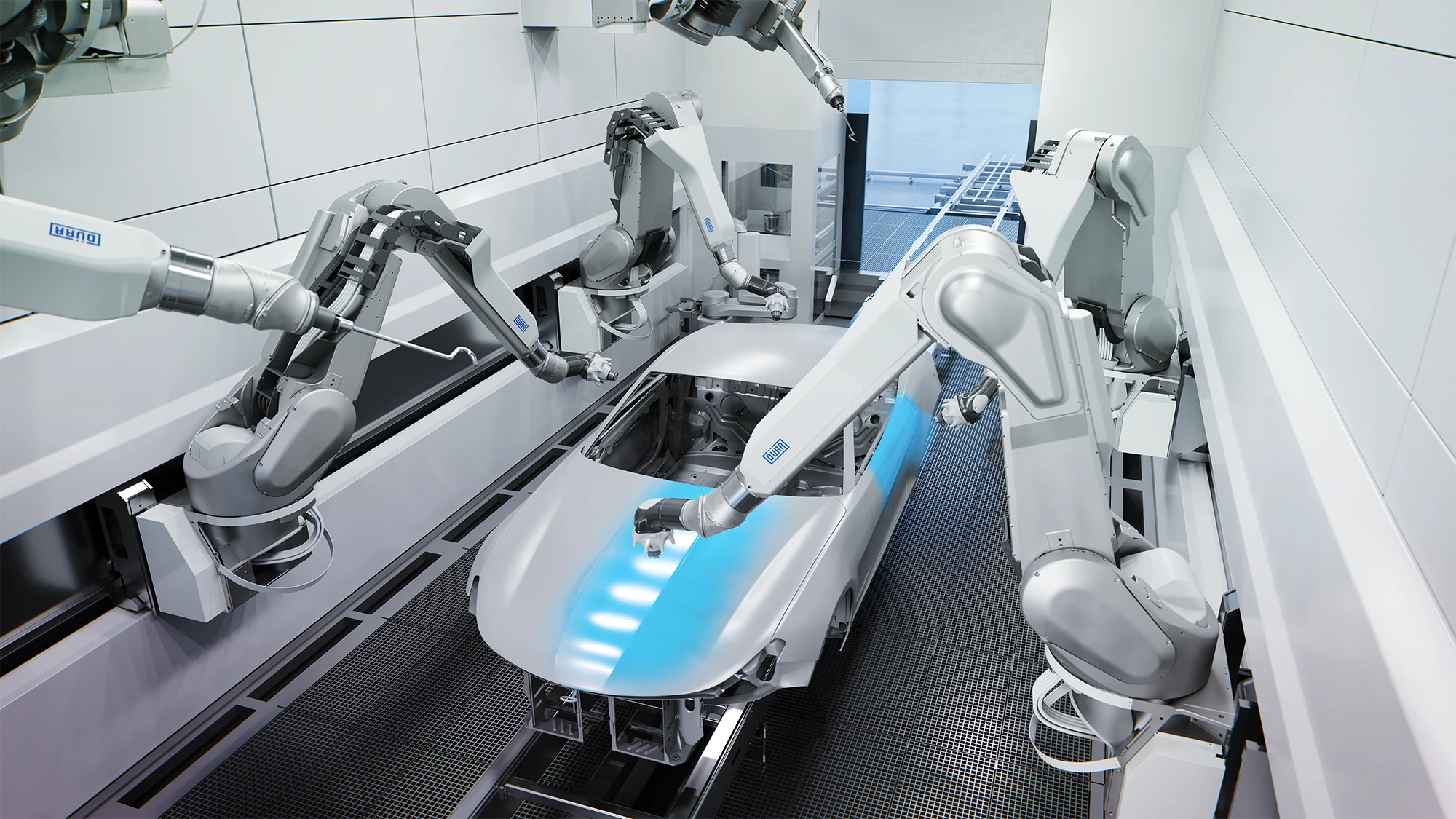

On November 12 and 13, the “Paint Shop of the Future” was presented, highlighting Dürr's innovative technological solutions and its strong commitment to sustainability. The Paint Shop of the Future breaks with traditional layouts by dividing industrial automotive painting into boxes or short process sections. This includes the integration of the EcoProBooth, which enables both interior and exterior painting of vehicle bodies within the same booth, central high-bay storage, the EcoProFleet automated guided vehicle system, and Dürr's DXQ family of intelligent software products, creating a flexible and scalable shop layout. This represents a significant advance in the customization and personalization of painting processes. The EcoPaintJet Pro, which enables the fully automatic painting of cars in two colors without overspray, also contributes to this. With the EcoBell4 rotary atomizer, color change becomes a matter of seconds – with the lowest possible coating and rinsing agent loss. This means faster cycle times, higher capacities and lower VOC emissions. Live demonstrations allowed participants to experience these innovative products firsthand.

The future of final assembly: NEXT.assembly

On November 14, the focus shifted to NEXT.assembly of the future, the latest innovations of Dürr’s final assembly portfolio. Dürr showcased its customized turnkey solutions for the automotive final assembly sector, aligned with its future-oriented vision. NEXT.assembly of the future is not a one-size-fits-all solution. Instead, it will be designed to meet each OEM’s requirements but rather a modular concept tailored to each OEM’s requirements. With five enabling innovations, including the ProLiner, Dürr's innovative Automated Guided Carrier (AGC), and the x-combined all-in-one testing stand, Dürr offers a flexible, modular, and scalable layout independent of specific building requirements. Through live demonstrations, Dürr offered incredible insight into cutting-edge solutions for the final assembly challenges of today and tomorrow.

Infinite possibilities for industrial painting and gluing

Dürr’s painting technology extends beyond the automotive industry and into other industrial sectors. The final day of the Open House focused on industrial painting and gluing technologies highlighting the ready2integrate concept and the new EcoSupply P Core paint supply system. These products bring new flexibility and high efficiency to automated painting solutions in industrial sectors.

In gluing technology, Dürr presented its skyroof gluing application technology and material supply systems, ensuring high-precision and consistent application with strict control over material consumption. These innovations were well received by attendees.

A firm commitment to green production

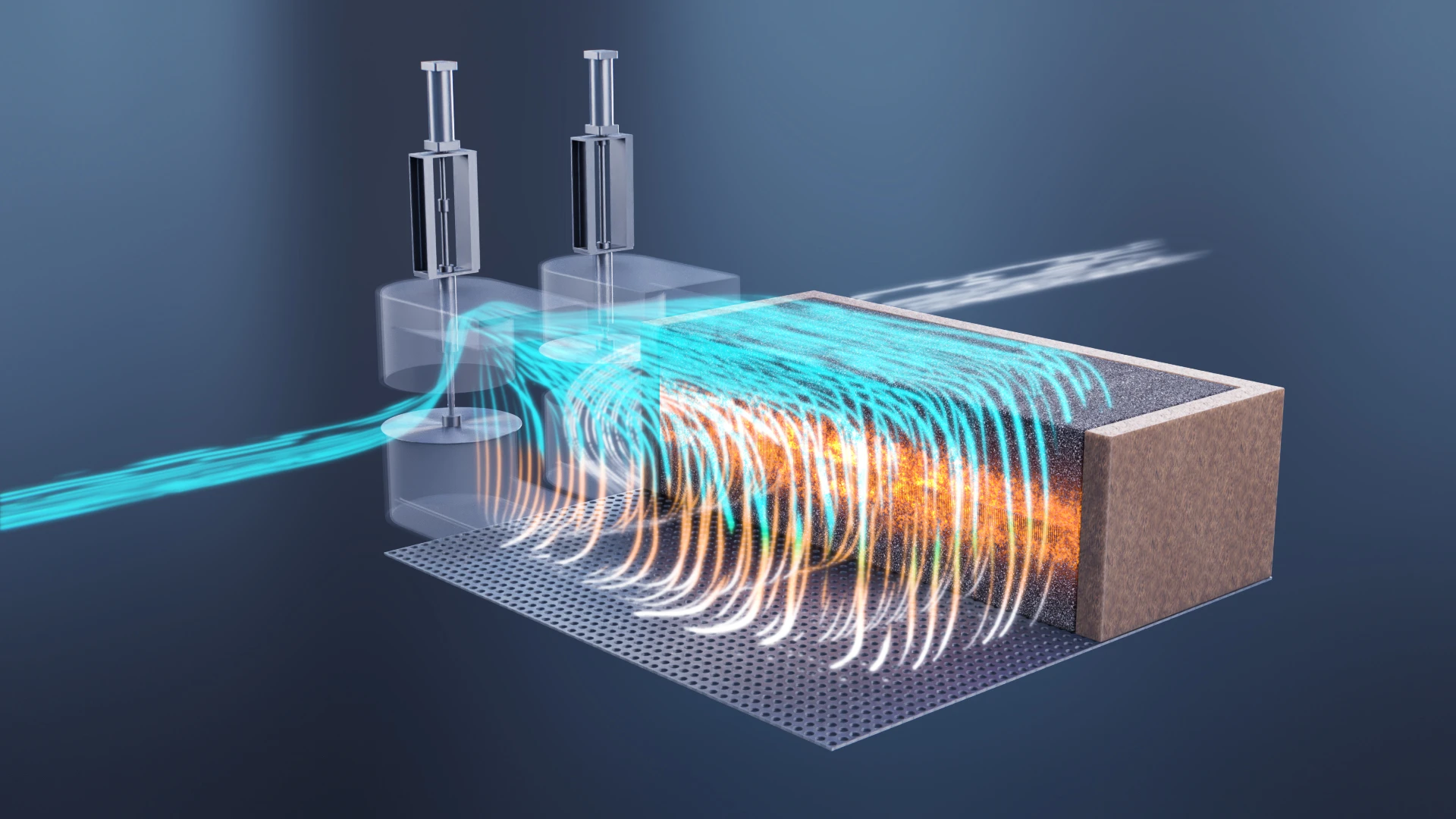

The final day also provided insights into Dürr’s environmental technology. This included exhaust air purification systems, emission reduction, and energy-saving solutions. Dürr’s clean technology products have been established in China since the late 1990s, supplying thousands of customized air pollution control systems for industries such as automotive, printing, chemical, pharmaceutical, and carbon fiber. New products, such as Oxi.X RV (electric RTO) and Oxi.X TR (TAR), drew strong interest. The Oxi.X RV uses advanced flameless technology for efficient exhaust gas purification, supporting carbon neutral industrial production.

More than 700 customers, partners, and media representatives from China, South East Asia, South Korea, and Japan attended the Dürr China Open House 2024, gaining deeper insights into Dürr's technologies and innovations through presentations, dynamic demonstrations, and personal exchanges.

Since Dürr installed the first oven for Volkswagen in Shanghai in 1983, the company’s pursuit of technological innovations, numerous installations have opened new perspectives and pathways for the Chinese automotive industry.

In the future, Dürr will continue to collaborate with its partners to address new challenges and seize new opportunities!

Feel the Innovative Spirit of the Future!