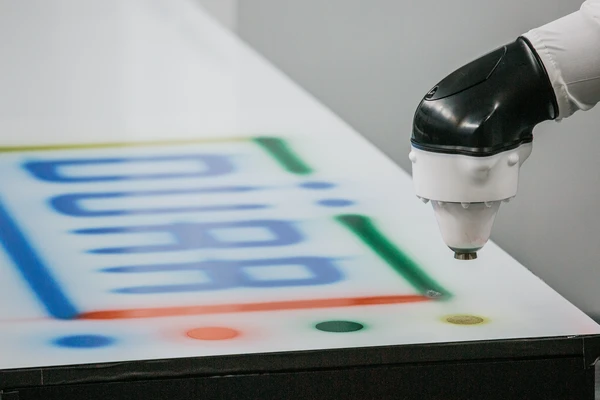

EcoBell4 Rotary atomizer

From green to red to yellow to blue. With the EcoBell4 atomizer generation and 4-main-needle technology, color change becomes a matter of seconds - with the lowest possible coating and rinsing agent losses. This means faster cycle times, higher capacities, less VOC emissions.

Demand-driven maintenance with RFID

With the EcoBell4 atomizers, we are introducing RFID technology into the spray booth. An RFID system monitors the atomizers in the spray booth and tracks each individual component. The information is provided for preventive and on-demand maintenance.

The RFID readers automatically identify each component based on a unique identification number. If components are installed incorrectly or replaced, the system warns the operator before the painting process even begins.

Dürr RFID transponders can both read and write operating data. This makes it possible to store extensive information chains, such as the number of operating cycles, speeds or maintenance history, directly on the components. A PC with a central database manages all RFID data from one or more painting lines. This allows the current status of the atomizer to be viewed. The precise history enables demand-driven maintenance that optimally utilizes the lifetime of components. This saves maintenance costs and increases plant availability.