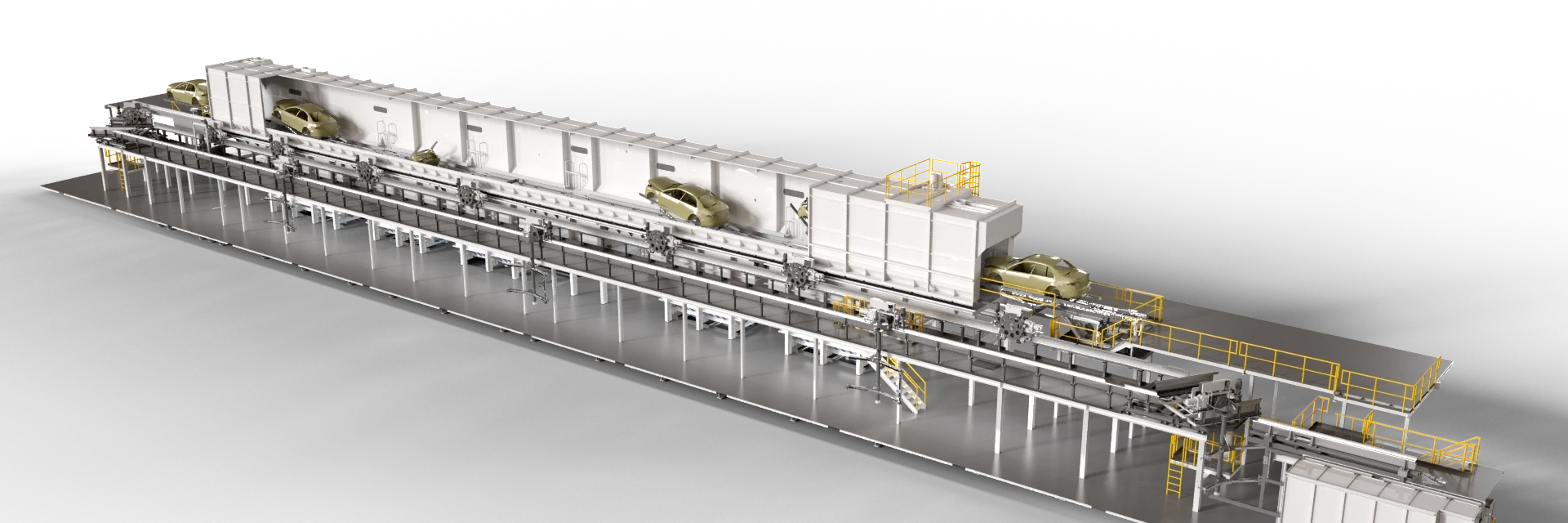

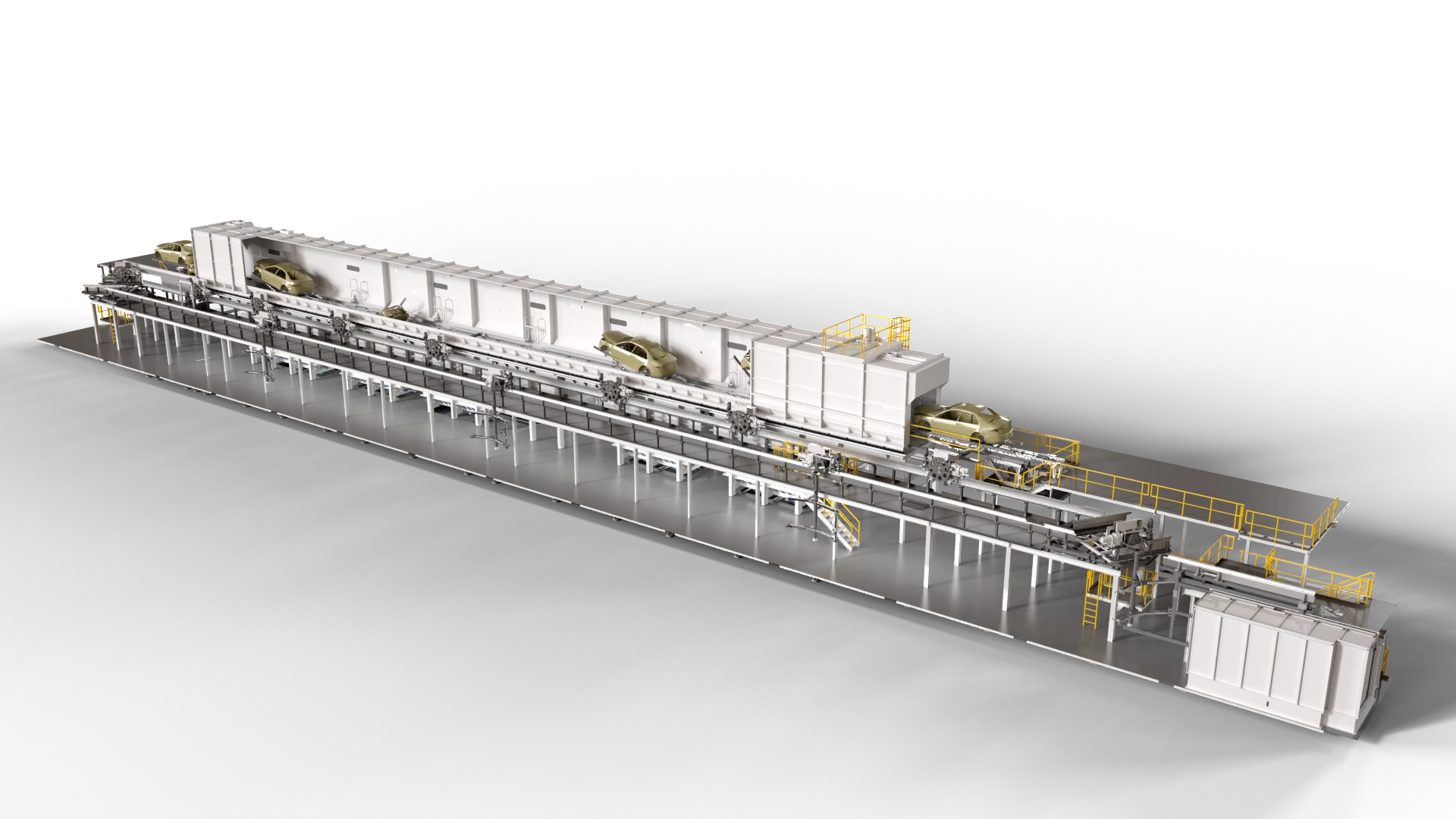

位于摩洛哥西北部的新工厂旨在成为资源节约的典范,显著提升了Stellantis集团旗下标致、雪铁龙和菲亚特等品牌纯电及混合动力汽车的产能。全新设计的涂装车间每小时可喷涂30辆车身,这与杜尔于2019年为Stellantis集团盖尼特拉工厂建造的首个涂装车间产能相同。

减少水、化学品和能源的消耗

该新车间引入了杜尔专门用于汽车车身前处理、电泳涂装的RoDip®旋转浸涂专利工艺,使车身围绕自身的轴线旋转,并根据不同车身类型优化了浸没、冲刷和沥水过程,显著提高了防腐蚀性能。与其他技术方案相比,RoDip®工艺消除了对入口和出口斜坡的需求,为每个浸槽节省了长达6米的长度,降低了浸槽的体积,大幅减少了水、化学品和能源的消耗,从而降低了运营成本和单位生产成本。

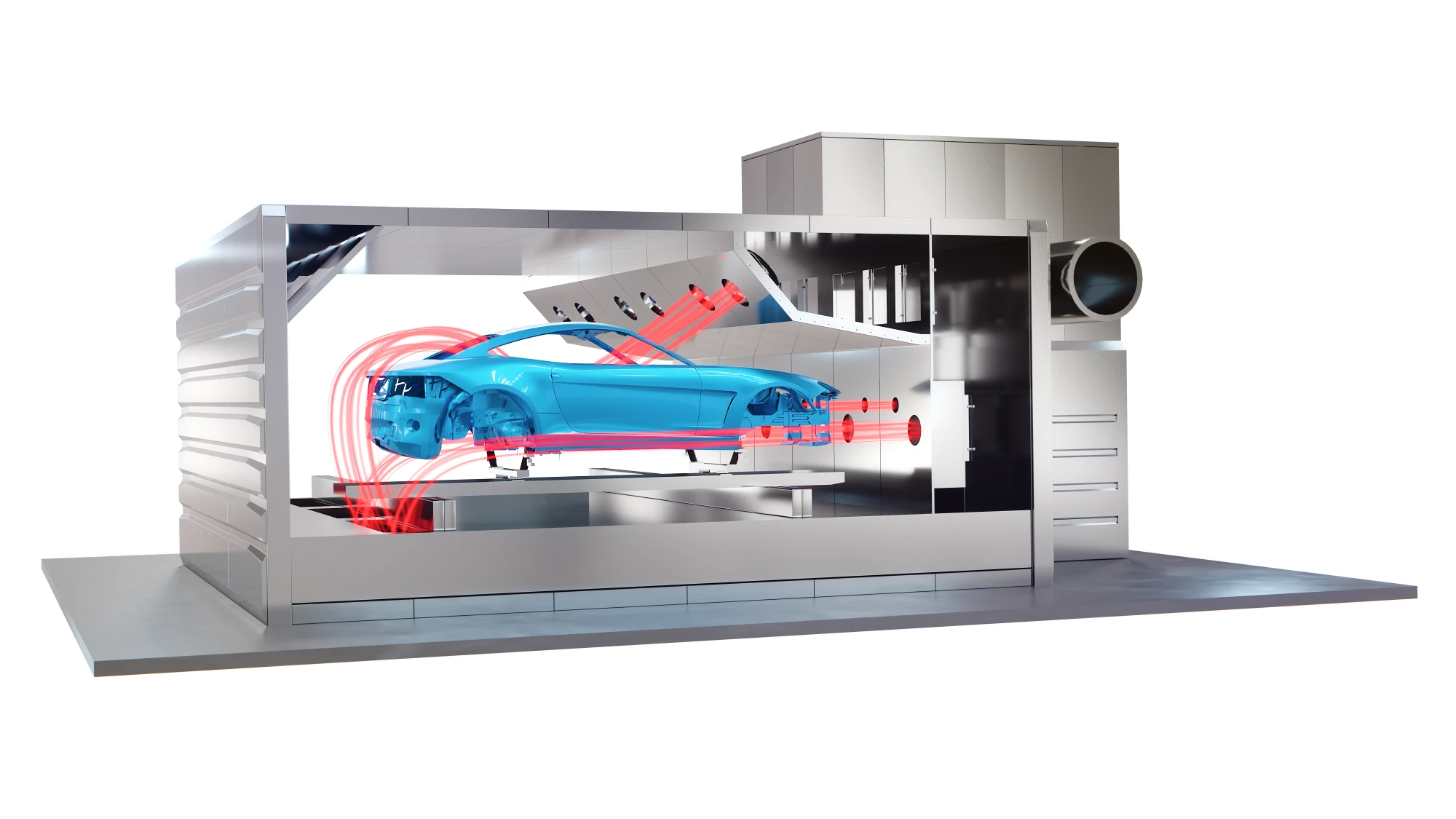

碳排放减少40%

除RoDip®工艺外,Stellantis集团还将首次采用杜尔EcoInCure烘房。该烘房采用创新的气流传导技术可由内而外均匀加热/冷却车身,这种独特的设计减少了部件的热应力,并将车身加热耗时最多缩短30%。盖尼特拉工厂采用最新一代的EcoInCure烘房全部由绿色电力驱动,降低了对化石燃料的依赖。与传统燃气烘房相比,该烘房可将涂装车间的碳排放减少40%,大大减少了碳足迹。

机器人利旧,实现资源利用最大化

由杜尔打造的新涂装车间还采用了湿碰湿喷涂工艺,显著节省了时间与能源。该工艺包含涵盖三个外喷站的双色喷涂,由杜尔改造并利用了Stellantis意大利工厂现有的机器人与应用技术。这些机器人均配备了EcoBell2高速旋转雾化器,可与车间现有设备无缝整合。此外,涂装车间还采用了从Stellantis欧洲各大工厂回收的供气装置、加热器和输送机等技术设备,并在新摩洛哥工厂进行改造,实现了它们的再利用。这种对现有生产设备进行改造和利旧的创新策略,不仅在苛刻的时间和预算限制下完成了涂装车间的建设,还确保了涂层的质量和性能,展现了杜尔对环境可持续性的承诺和对资源高效利用的不懈追求。