Carbon-neutral drying made easy

Jul 1, 2024

Electrifying gas ovens can reduce paint shop CO2 emissions by up to 40 percent

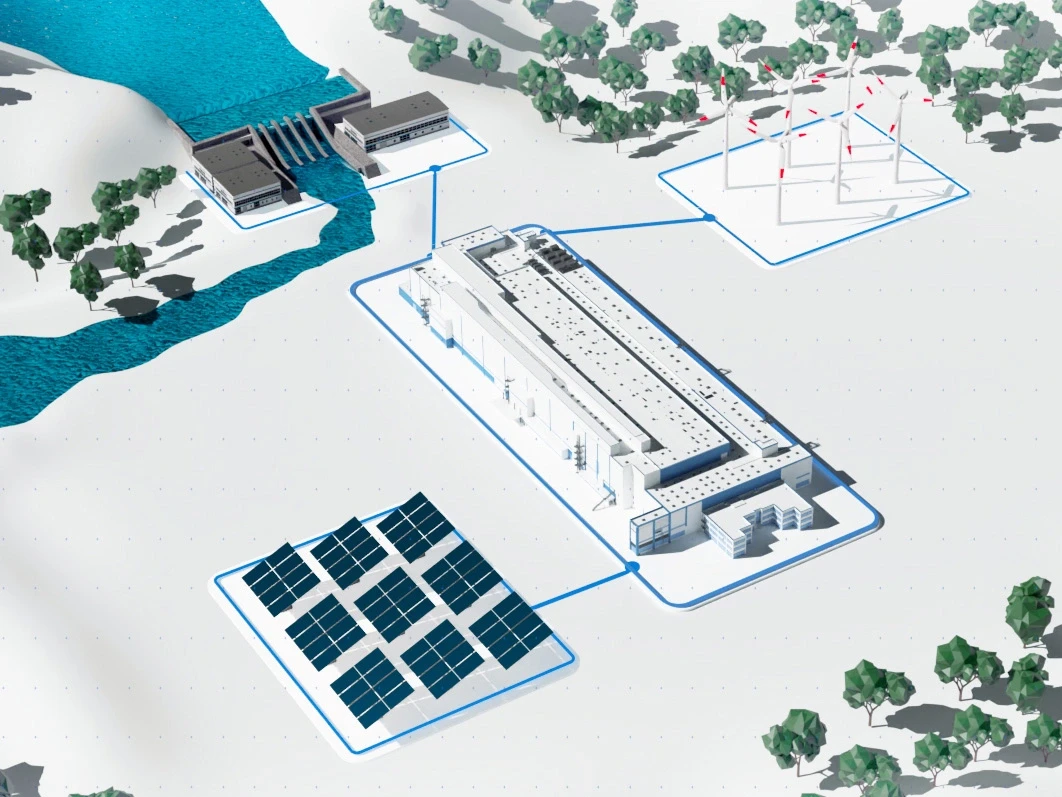

For many vehicle manufacturers, the drying process is a significant obstacle to achieving CO2-neutral production. The drying phase consumes more energy than any other part of the car body painting process and has a large carbon footprint. The solution? Electrify the oven. Dürr is the first supplier to electrify all body ovens in its portfolio. The company’s first pilot project using green electricity – an oven in a Scandinavian paint shop that has been operational since 2018 – demonstrates that the drying process still meets the same high-quality standards.

Transitioning from natural gas to renewable energy, such as green electricity, can reduce a conventional paint shop’s CO2 emissions by approximately 40 percent in one go, a significant step toward climate-neutral production and increased supply security.

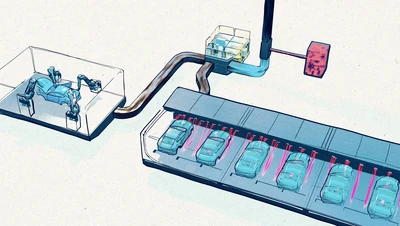

All Dürr ovens – from their classic models to their compact EcoSmartCure and the innovative EcoInCure that dries bodies from the inside – utilize electricity, the energy source of the future. The focus is not only on electrifying new ovens but also on converting existing ones. Our brownfield experts perform individual assessments to develop an extremely cost-effective conversion plan that minimizes the scope of work and time needed.

How does electrification impact costs?

In the medium term, fossil fuel prices are expected to continue rising, while renewable energy costs are likely to fall as production capacity increases.

To help car manufacturers make their production processes more cost-effective using climate-friendly green electricity right now, we developed an integrative concept based on various energy efficiency modules. We can introduce several measures to minimize energy consumption using state-of-the-art insulation, skidless conveyor systems, highly efficient heat recovery solutions, and smart energy efficiency software.

Heiko Dieter, Product Manager, Dürr Systems AG

How can oven heating and air pollution control processes benefit from one another?

Electricity also powers the Oxi.X RV air pollution control system, which operates on the regenerative thermal oxidation (RTO) principle. This technology includes a highly effective internal heat recovery system and operates at a high energy efficiency standard, requiring almost no additional electricity. The remaining energy in the exhaust airflow can be used to preheat the fresh air, significantly reducing energy losses from the exhaust air.

We are the only paint shop supplier to offer a complete package for electrifying the oven and air pollution control system. We can reduce energy consumption and keep operating expenditures to a minimum by combining energy efficiency technologies with products from our portfolio. Electric ovens for drying car bodies pose no risks to our customers, and electrification does not impact curing conditions. As always, customers can rely on the quality of Dürr systems and on achieving optimum drying results.

Heiko Dieter, Product Manager, Dürr Systems AG

How can energy supply be managed to meet requirements?

The DXQ EcoSmart VEC module proactively manages the fresh and exhaust airflow rates and is critical in improving energy efficiency. The intelligent software system minimizes oven electricity consumption by adjusting the exact energy usage according to the number of bodies in the oven and when it operates under partial load or when production is interrupted.