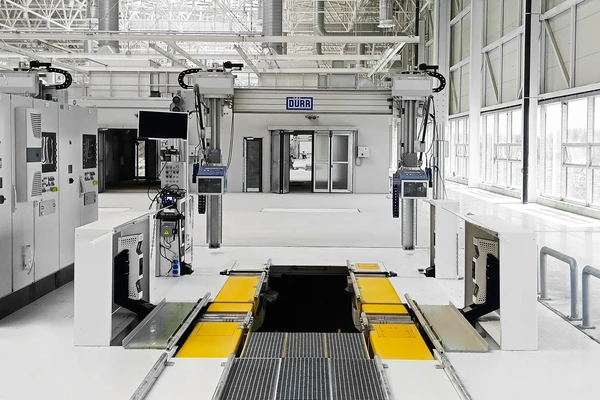

x-combined - All-in-one testing

The x-combined is Dürr's answer to state-of-the-art vehicle technologies and production requirements.

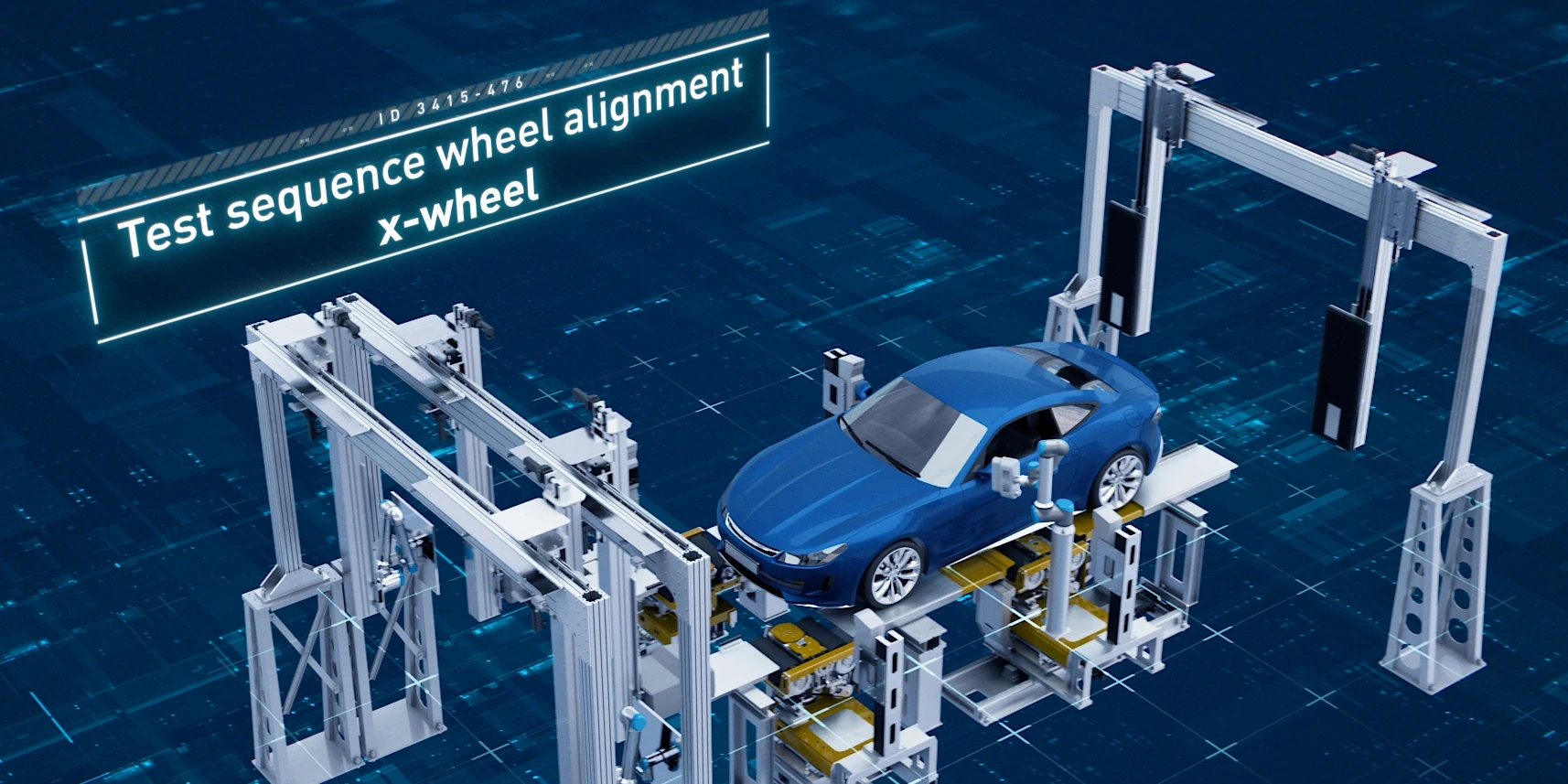

Combined test stand for wheel alignment and brake/sensor testing

The x-combined is the first combined test stand that can be used for wheel alignment and adjustment as well as brake and sensor testing. Depending on the respective cycle time, headlight adjustment and calibration of the driver assistance systems can be integrated as an additional option.

The testing and adjustment process can be carried out fully automatically or manually, including vehicle transportation.

The main component of the x-combined is the newly developed wheel support. It enables wheel alignment, brake and sensor tests to be carried out on one test stand, thus reducing the number of test stations, process times, space requirements and infrastructure measures.

Customer benefits

- Reduction of test stations and space requirements

- Reduction of infrastructure measures (pits, technical building equipment, etc.)

- Reduction in manpower due to reduction of test stations and option for full automation

- Reduction of process times (there is no need to relocate and re-identify the vehicle, for example)

- Scalable in terms of test content and production figures

- Fast and flexible adaptation to changing production requirements

- Designed for all kinds of passenger vehicles

- All tests are carried out without a driver in the vehicle

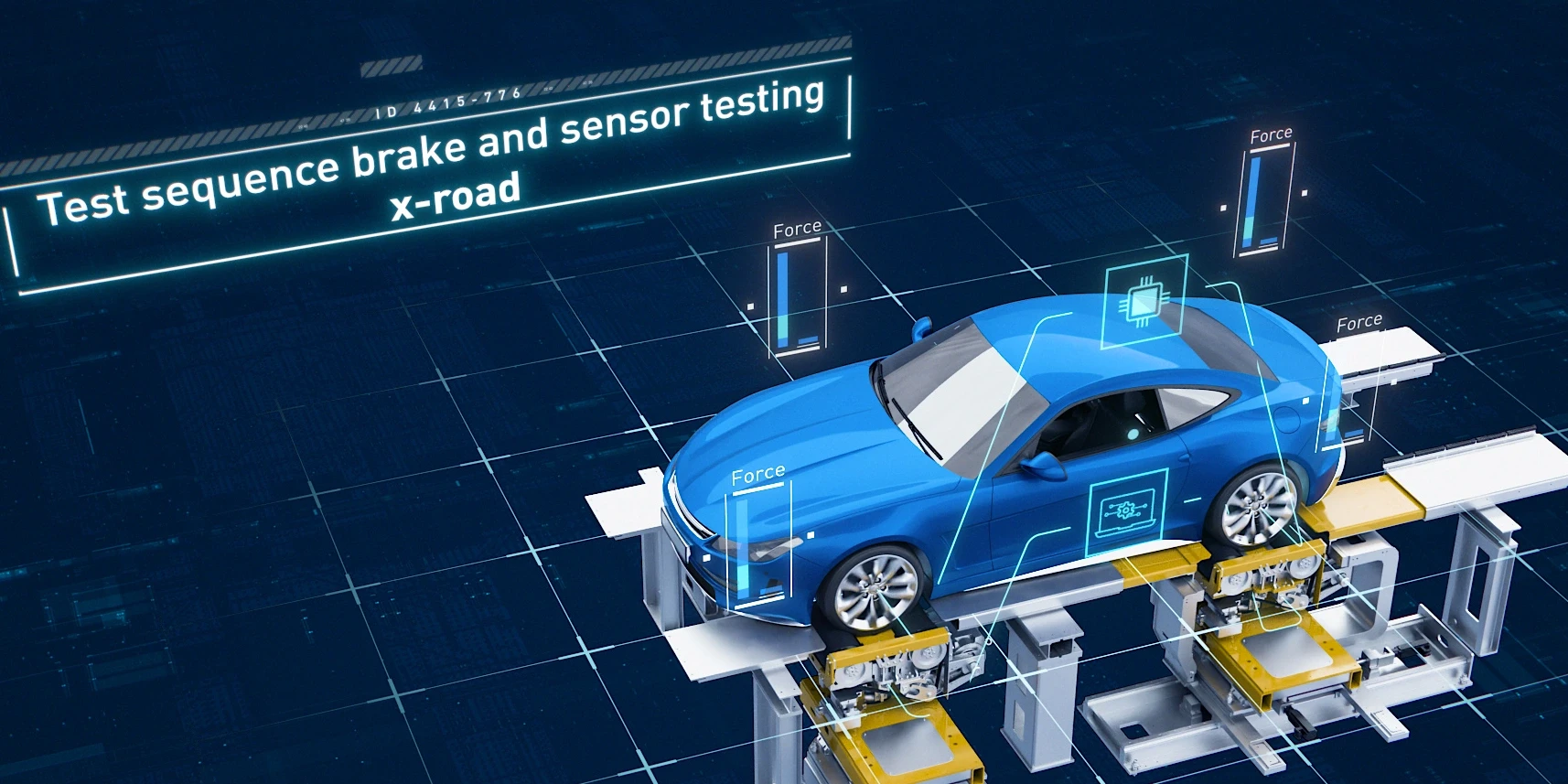

- Toe/camber measurement incl. runout compensation and height measurement

- Brake force measurement up to 4000 N per wheel

- Test speed up to 30 km/h

- Cycle time approx. 3–5 min. depending on the specified scope of testing

- Static brake test

- Roll test up to 30 km/h

- Sensor test

- Sensor valve test (ESP test)

- Recuperation test for electric vehicles